The emergence of frequency converters has brought innovation to industrial automation control and motor energy saving.

Industrial production is almost inseparable from inverters, and even in everyday life, lifts and inverter air conditioners have become an indispensable part of the process, and inverters have begun to penetrate into all corners of production and life.

However, inverters have also brought with them many unprecedented problems, of which damage to electric motors is one of the most typical phenomena.

Many people have already discovered the phenomenon of inverter damage to motors.

For example, a water pump factory, in the last two years, his customers frequently reported that the pumps were damaged during the warranty period.

In the past, however, this pump factory had been very reliable in terms of product quality. After investigation, it was found that these damaged pumps were driven by frequency converters.

Although the phenomenon of inverters damaging motors is a growing concern, the mechanisms that cause it are not yet clear, let alone how to prevent it.

The purpose of sharing this article is to address these confusions.

Damage to electric motors from frequency converters

Damage to the electric motor from the inverter includes two aspects, damage to the motor windings and damage to the motor bearings.

This is shown in the diagram below:

This damage generally occurs within a few weeks to a dozen months, the specific time is related to the brand of the inverter, the brand of the electric motor, the power of the electric motors, the carrier frequency of the inverter, the length of the cable between the inverter and the electric motors, the ambient temperature and many other factors.

Early and unexpected damage to the electric motors brings huge economic losses to the production of the company.

This loss is not only the cost of motor repair and replacement, but also the economic loss caused by unexpected production stoppages.

Therefore, when using inverter-driven motors, sufficient attention must be paid to the issue of motor damage.

Difference between inverter drive and industrial variable frequency drives

It is important to understand the mechanism by which an industrial frequency motor is more likely to be damaged under inverter-driven conditions with driven equipment.

First understand how the voltage at which the inverter drives the motor differs from the I.F. shaft voltages.

Then understand how this difference has an adverse effect on the motor.

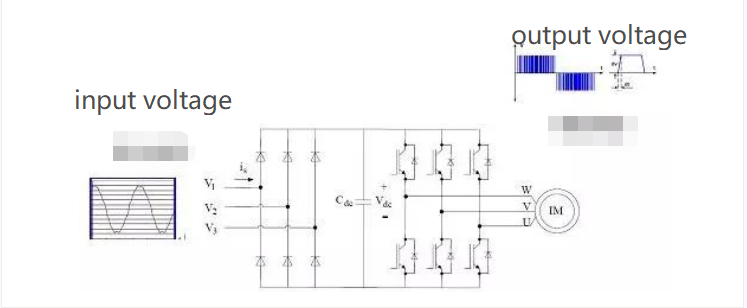

The basic construction of an inverter is shown in Figure 2 and consists of two parts: the rectifier circuit and the inverter circuit.

The rectifier circuit is a DC voltage spikes output circuit consisting of a common diode and filter capacitor, while the inverter circuit converts the DC voltage into a pulse width modulated voltage waveform (PWM voltage).

Therefore, the voltage waveform of the inverter driving the motors are a pulse waveform with varying pulse width, rather than a sinusoidal voltage waveform.

Driving a motor with pulsed voltage is the root cause of the motor's vulnerability to damage.

Mechanism of damage to motor windings by frequency converters

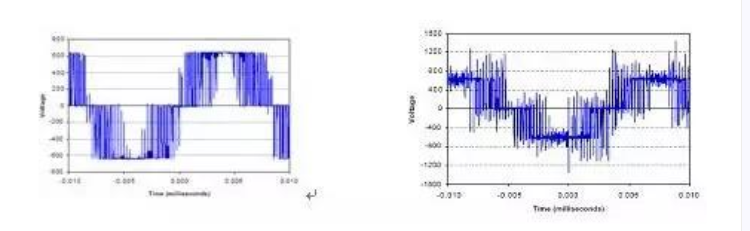

When the pulsed voltage is transmitted over the cable, if the impedance of the cable does not match the impedance of the load, a reflection will occur at the load end.

The reflection results in a superposition of the incident wave and the reflected wave, creating a higher voltage, which can reach a maximum amplitude of twice the DC bus voltage, which is approximately equivalent to three times the input voltage of the inverter, as shown in Figure 3.

The excessively high spike voltage is added to the coils of the motor stator, causing voltage shocks to the coils, and frequent overvoltage shocks can lead to premature motor failure.

The actual life of an inverter-driven motor after it has been subjected to a spike voltage shock is related to a number of factors including, temperature, contamination, vibration, voltage, carrier frequency and the workmanship of the coil insulation for the electrical automation industry.

The higher the carrier frequency of the inverter, the closer the output current waveform is to a sine wave, which will reduce the motor's operating temperature and thus extend the life of the motor insulation.

However, a higher carrier frequency means that a greater number of limit voltage spikes are generated per second and the number of shocks to the motor is greater.

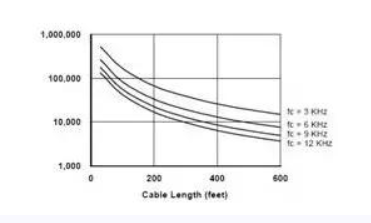

Figure 4 gives the variation of insulation life as a function of cable length and carrier frequency.

As can be seen from the graph, for a 200 foot long cable, the insulation life decreases from approximately 80,000 hours to 20,000 hours (a fourfold difference) when the carrier frequency is increased from 3 kHz to 12 kHz (a fourfold change).

Influence of carrier frequency on insulation of electric motors

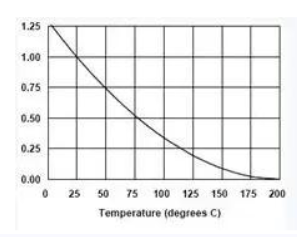

The higher the temperature of the motor, the shorter the life of the motor insulation, as shown in Figure 5, when the temperature rises to 75°C , the life of the motor is only 50%.

Motors driven by frequency converters will have a much higher motor temperature than if they were driven by an industrial frequency voltage, as the PWM voltage contains more high frequency components

Mechanisms by which frequency converters damage motor bearings

The inverter damages the bearings of the motor because there is a current flowing through the bearings and this current is in an intermittent connected circuit, the intermittent connected circuit creates an arc and the arc burns the bearings.

There are two main causes of current flowing through the bearings of an AC new motor.

Firstly, induced peak voltages from an unbalanced internal electromagnetic field, and secondly, high frequency current paths caused by stray capacitors.

The internal magnetic field of an ideal AC induction motor is symmetrical and when the currents in the three phase windings are equal and the phases are 120? apart, no voltage is induced in the shaft rod of the motor.

When the PWM voltage output from the inverter causes the magnetic field inside the new motors to be asymmetrical, a common mode voltage will be induced on the motor shaft rod in the range of 10 to 30V, which is related to the drive voltage, the higher the drive voltage, the higher the voltage on the shaft rod.

When the value of this voltage exceeds the insulating strength of the lubricant in the bearing, a current path is formed.

At some point during the rotation of the axle rod, the insulation of the lubricating oil again blocks the current.

This process is similar to the on/off process of a mechanical switch.

This process generates an electric arc which burns the surfaces of the shaft, ball and bowl, forming pits.

If there is no external vibration, the small craters do not have an excessive effect, but when there is external vibration, the craters are created and this has a significant effect on the operation of the motor from the electric motor manufacturers.

In addition, experiments have shown that the voltage peaks on the shaft rod is also related to the fundamental frequency of the inverter output voltage; the lower the fundamental frequency, the higher the voltage on the shaft rod and the more serious the bearing damage.

In the early stages of motor operation, when the lubricant temperature is low, the current amplitude is 5-200mA, such a small current will not cause any damage to the bearings.

However, after the motor meets the running for a period of time, as the lubricant temperature rises, the peak current will reach 5-10A, which will create flying arcs that will form small pits on the surface of the bearing components.

Welcome to share with us more information about electric motors in the comments area!

Any inquiry about electric motor, please contact the professional electric motor manufacturer in China as follows:

Dongchun motor has a wide range of electric motors that are used in various industries such as transportation, infrastructure, and construction.

Get a prompt reply.