Асинхронный двигатель с однофазным источником питания переменного тока называется однофазным асинхронным двигателем.

Однофазный асинхронный двигатель требует только однофазной мощности переменного тока, поэтому он удобен в использовании, широко используется и имеет преимущества простой структуры, низкой стоимости, низкого шума, низких помех с радиосистемой и т. Д.

Таким образом, он часто используется в бытовых приборах и малой электроэнергии с небольшой мощностью, такой как электрические вентиляторы, стиральные машины, холодильники, кондиционеры, капюшоны, электрические упражнения, медицинское оборудование, небольшие вентиляторы и домашние водяные насосы и т. Д.

1. Классификация однофазного асинхронного двигателя

1 、 Однофазные двигатели типа с сопротивлением

Его статор встроен с обмоткой основной фазы и вторичной фазовой обмоткой, и эти две обмотки и ось в пространстве на 90 градусов электрического угла.

Вторичная фазовая обмотка обычно натягивается с помощью приложенного резистора через центробежное отверстие, соединенное параллельно с обмоткой основной фазы и соединено с источником питания вместе.

Когда однофазный двигатель начинается до тех пор, пока скорость не достигнет 75-80% от синхронной скорости, открывается центрифуга, а контакт центробежного переключателя отключается.

2 、 Конденсатор стартового типа однофазные двигатели

Он в основном такой же, как и однофазный мотор, начиная с сопротивления, на статоре также есть два набора обмоток с основной фазой и вторичной фазой под электрическим углом 90 градусов.

Вторичная обмотка и внешний конденсатор соединены с центробежным переключателем, параллельно с основной обмоткой и соединены с электрическим источником питания вместе, также, когда 75% ~ 80% синхронной скорости достигаются, вторичная обмотка отключается и становится однофазными двигателями индукции.

Мощность такого рода электродвигателя составляет 120 Вт ~ 3700 Вт.

3 、 Конденсатор работает тип однофазного двигателя

Статорная обмотка такого рода двигателя также является двумя наборами обмотки, и структура в основном одинакова, но технический индекс двигателя, управляемого конденсатором, лучше, чем другие формы двигателя.

Несмотря на то, что он имеет лучшую производительность, начальная производительность плохая, то есть начальный крутящий момент низкий, а чем больше способности двигателя, тем меньше соотношение запуска крутящего момента к рейтингу крутящего момента.

Следовательно, способность двигателей конденсаторов не большая, как правило, менее 180 Вт.

4 、 однофазный конденсатор, запуск и работающий однофазный двигатель

Этот вид однофазного двигателя обращается к двум конденсаторам во вторичной обмотке, один из них отключается после начала через центробежный переключатель; Другой всегда участвует в работе вторичной обмотки.

Из этих двух конденсаторов стартовый конденсатор имеет большую емкость, в то время как у бегового конденсатора небольшая пропускная способность.

Этот вид однофазного конденсатора, запущенного и работающего мотор, интегрирует преимущества однофазного конденсатора и моторного моторного конденсатора.

Таким образом, этот вид однофазного двигателя имеет лучшую начальную производительность и производительность работы, и мощность может быть увеличена на 1-2 уровня емкости в одном номере сиденья, а мощность может достигать 0,75 кВт до 7,5 кВт.

5 、 Однофазный мотор с однофазным затененным полюсом.

Это асинхронный двигатель с простой структурой, как правило, с выпуклой статором полюса, основной обмоткой является централизованная обмотка, в то время как вторичная фазовая обмотка представляет собой кольцо с коротким кругом, называемое заштрихованным катером.

Производительность такого рода однофазного двигателя плохая, но из -за твердой структуры и дешевой цены количество производственного количества такого рода двигателя по -прежнему велика, но выходная мощность обычно составляет не более 20 Вт.

2. Принцип работы однофазных двигателей

В двигателях переменного тока, когда обмотка статора проходит через ток переменного тока, создается магнитомотивная сила якоря, что оказывает большое влияние на преобразование энергии и эксплуатационные характеристики однофазных двигателей индукции.

Таким образом, однофазная обмотка переменного тока передается в однофазный переменный ток с образованием пульсирующего магнитного потенциала, который может быть разложен на два вращающихся магнитных потенциала равной амплитуды и противоположной скорости, таким образом устанавливая прямое и обратное магнитное поле и в воздушном зазоре.

Эти два вращающихся магнитных поля разрезают проводник ротора и генерируют индуцированный электрический потенциал и индуцированный ток в проводнике ротора соответственно.

Этот ток взаимодействует с магнитным полем для получения прямого и обратного электромагнитного крутящего момента.

Передний электромагнитный крутящий момент пытается заставить ротор вращаться вперед; Обратный электромагнитный крутящий момент пытается заставить ротор вращаться назад.

Суперпозиция этих двух крутящих моментов является синтетическим крутящим моментом, который движет однофазной индукционно -индукционным вращением.

3. Структурные характеристики и использование однофазного индукционного двигателя

Основные характеристики асинхронного двигателя заключаются в том, что обмотка ротора не должна быть подключена к другим источникам питания, а его ток статора получается непосредственно из системы электростанции однофазного питания AC; По сравнению с другими трехфазными двигателями структура асинхронного двигателя проста, легко изготавливать, использовать и поддерживать, с высокой работой достоверностью, легким весом и низкой стоимостью.

Однофазный асинхронный двигатель невелик в однофазной мощности и в основном превращается в небольшие электродвигатели.

Он имеет широкий спектр применений, таких как бытовые приборы (стиральные машины, холодильники, электрические вентиляторы), электроинструменты (такие как ручные упражнения), медицинское оборудование, инструменты автоматизации и т. Д.

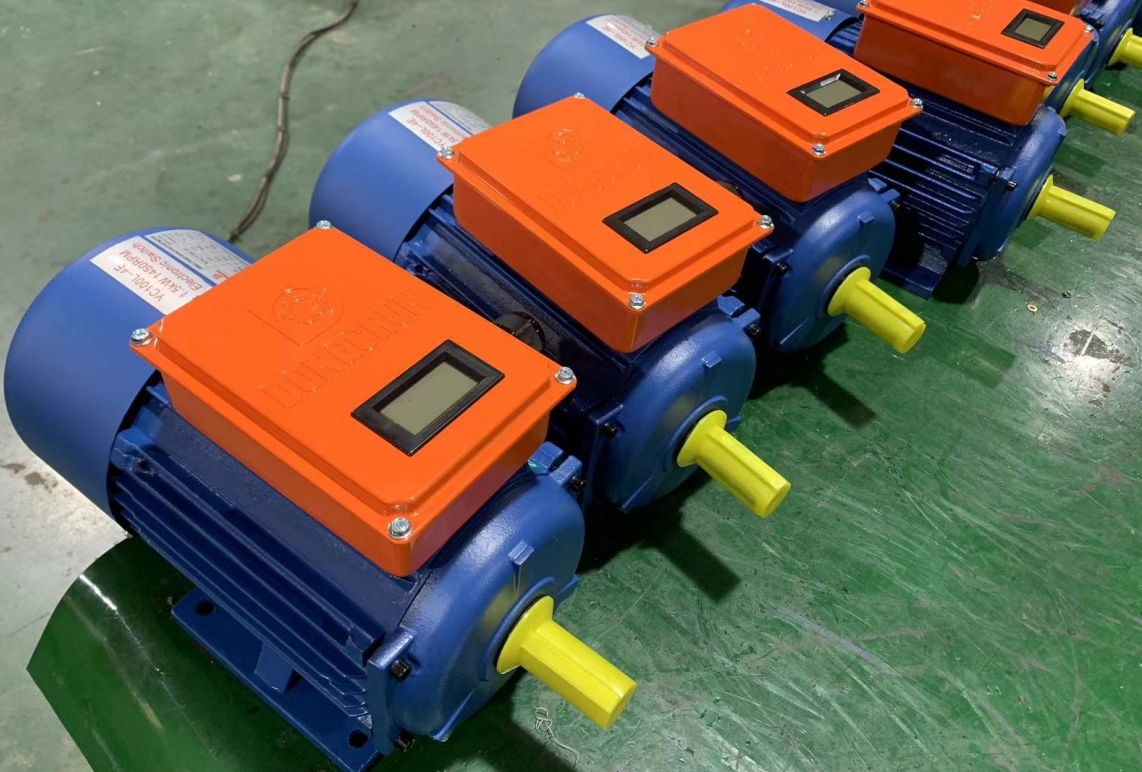

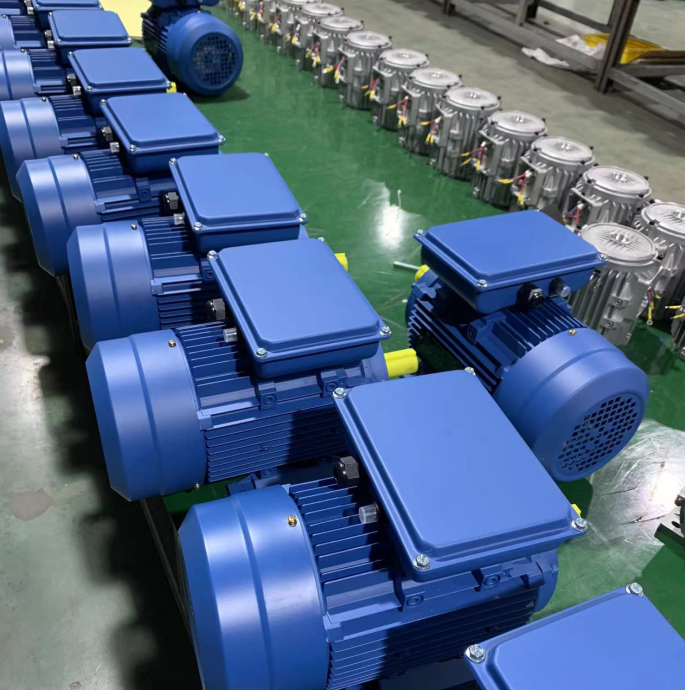

Если вы хотите получить цену на однофазные двигатели, пожалуйста, свяжитесь с лучшим однофазным производителем двигателя -Donghun Motor China

Dongchun Motor предлагает широкий ассортимент электродвигателей, которые используются в различных отраслях, таких как транспорт, инфраструктура и строительство.

Получите оперативный ответ.