What is the difference between a brushless motor and a brushed motor?

What is the difference between a synchronous motor and an asynchronous motor?

How about the wound rotor induction motor?

Are all servo motors AC motors?

Are all servo motors synchronous motors?

Do stepper motors belong to DC motors or AC motors?

Is a servo motor a servo motor? ......

The sages once said: If knowledge is not systematic, what is the difference between it and a paragraph?

But the sage book on that long-winded text, that fanciful terminology, that plausible explanation, really look at people in the clouds.

I have also searched the Internet for a long time, did not find a more systematic explanation of the electric motors structure and principle of classification, so they took a lot of effort to query and organize a copy.

This article tries to explain the systematic knowledge in plain language, and uses a lot of animation and pictures to express the obscure knowledge vividly.

Due to my limited knowledge, it is inevitable that there are many mistakes, please correct the experts, please do not hesitate to give advice.

1. a diagram to explain the basic types of electric motors

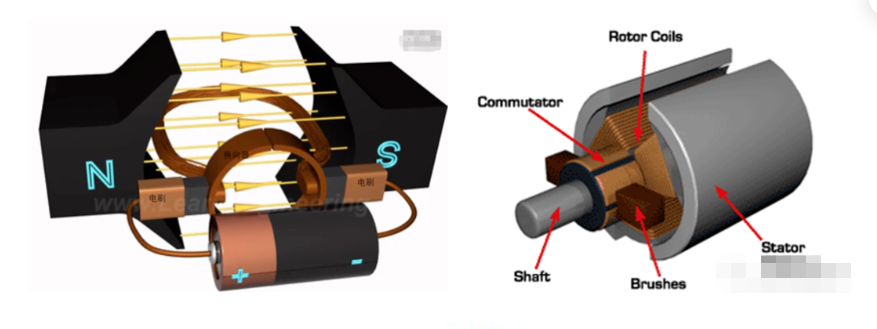

2. DC electric motor - brush motor

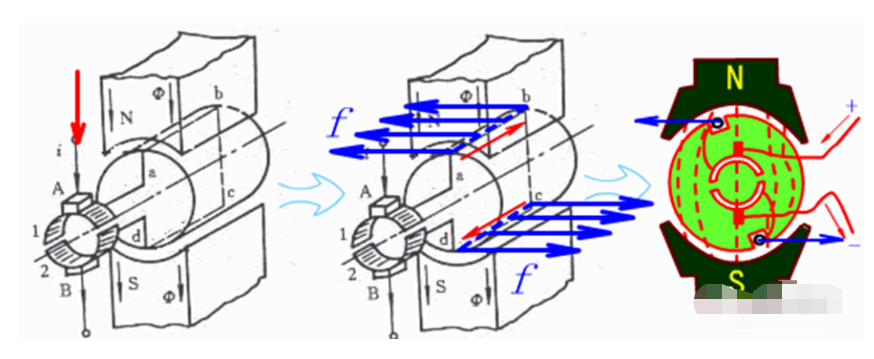

Read the secondary school physics of the bully scum know, in order to study the energized conductor in the magnetic field force of that thing, we have trained the left hand into a broken palm, which is exactly the principle of DC induction motor.

All electric motors are composed of stator and rotor, in DC electric motors, in order to make the rotor turn, you need to constantly change the direction of the current, otherwise the rotor can only turn half a turn, this is like a bicycle pedal.

That's why DC motors need commutators.

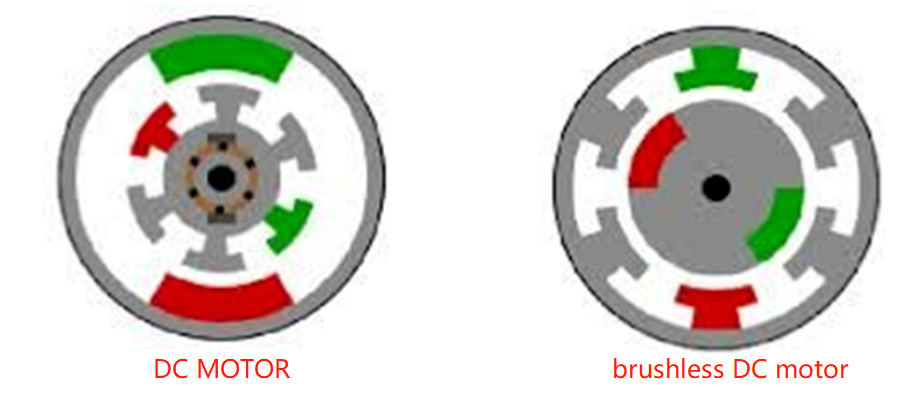

Broadly speaking, brushed DC motors include brushed motors and brushless motors.

Brush motor is also called DC induction motor or carbon brush motor, often referred to as brush DC motor.

It uses mechanical commutation, the external pole does not move the internal coil (armature) moving, commutator and rotor coil rotating together, brushes and magnets are not moving, so the commutator and brush friction friction, complete the current direction switching.

Brush motor disadvantages.

1, mechanical commutation of sparks generated by the commutator and brush friction, electromagnetic interference, high noise, short life.

2, poor reliability, many failures, requiring frequent maintenance.

3, due to the presence of commutator, limiting the rotor inertia, limiting the maximum speed, affecting the dynamic performance.

Since it has so many shortcomings why it is still commonly used, because it is high torque, simple structure easy maintenance (i.e. change carbon brushes), cheap.

2. DC motors - brushless motors

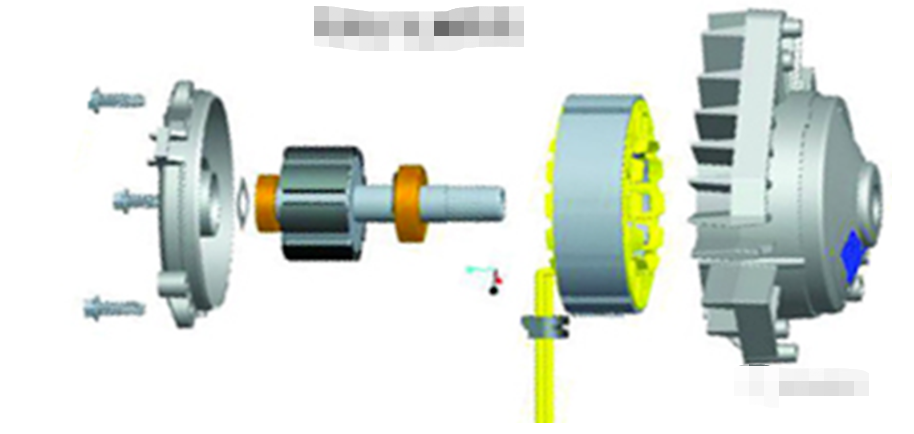

Brushless motor is also called DC inverter motor (BLDC) in some fields, it uses electronic commutation (Hall sensor), the coil (armature) does not move the magnetic poles move, then the permanent magnet can be outside the coil or inside the coil, so there is an external rotor brushless motor and internal rotor brushless motor

Brushless motors are constructed in the same way as permanent magnet synchronous motors.

However, a single brushless motor is not a complete power system. Brushless basically must be controlled by a brushless controller, also known as an ESC, to achieve continuous operation.

It is the brushless electronic governor (ESC) that really determines its performance.

Generally, there are two types of drive currents for brushless motors, one is a square wave and the other is a sine wave.

Sometimes the former is called a DC brushless motor, and the latter is called an AC servo motor, which is exactly a kind of AC servo motor.

Brushless motors operate in different ways, and can be divided into inner-rotor brushless motors and outer-rotor brushless motors.

The inner rotor is three-phase, which is more expensive.

The outer rotor is usually used in single-phase, the price of the people, mass production has been close to the carbon brush motor, so in recent years is widely used.

The price of the outer rotor three-phase is close to the price of the inner rotor.

Well, as you can guess, the disadvantage of brush motors is the point of brushless motors.

It has high efficiency, low energy consumption, low noise, long life, high reliability, servo control, stepless frequency conversion speed (up to a very high speed) and other advantages.

It is relatively smaller than the brush DC motor, control than the asynchronous AC motor is simple, the starting torque is large overload capacity, as for the disadvantages ...... is more expensive than the brush, bad maintenance.

2. DC motor - speed control principle

DC induction motor speed regulation: the so-called speed regulation, that is, by adjusting the motor speed to obtain the required torque.

permanent magnet dc motor by adjusting the voltage, series resistance, change the excitation can be speed, but the actual voltage adjustment is the most convenient and most commonly used, the main use of PWM speed regulation.

PWM is actually through the high-speed switch to achieve DC voltage regulation, a cycle, open a long time, the average voltage is high, off a long time, the average voltage is low, very convenient to adjust, as long as the switch speed As long as the switching speed is fast enough, the harmonics of the grid is less, and the current is more continuous.

However, the brushes and commutator wear for a long time, and at the same time there is a huge current change during commutation, which is very easy to produce sparks.

The commutator and brushes limit the capacity and speed of DC induction motor, which makes the speed regulation of DC induction motor meet a bottleneck.

For brushless DC induction motor, the speed control only controls the input voltage on the surface.

But the motor's self-control frequency control system (brushless DC motor itself comes with a rotor position detector and other rotor position signal acquisition device, using the rotor position signal of this device to control the variable voltage frequency control device phase change moment) automatically controls the frequency according to the variable voltage, which is almost the same as the DC (brushed) motor, very convenient. Very convenient.

Because the rotor uses permanent magnets, no special excitation winding, in the case of the same capacity, the motor is smaller, lighter, more efficient, more compact, more reliable operation, better dynamic performance, in the drive of electric vehicles and other aspects have been widely used.

3. Three-phase AC motors - asynchronous motors

AC motors are divided into synchronous motors and asynchronous motors, synchronous motors are mostly used in generators and asynchronous motors are mostly used in electric motors. They are squirrel cage induction motor.

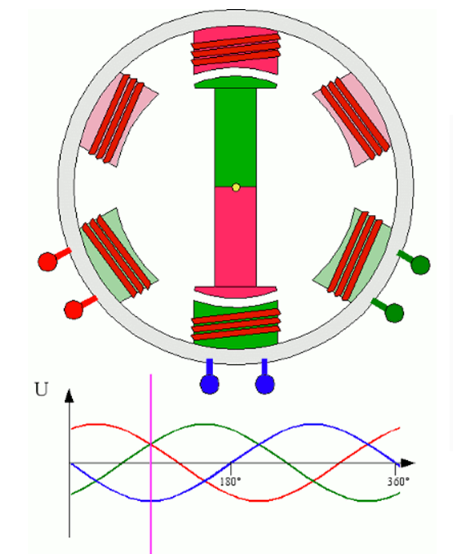

The housing of the motor is the stator, and there are three symmetrical AC windings on the stator.

As the sequence of the three phases changes, a rotating synthetic magnetic field is formed, and the rotational speed of the magnetic field is the synchronous speed.

The synchronous speed n=60f/p, f is the frequency, p is the number of pole pairs, for example, for a 2-pole motor connected to the national grid 50Hz (i.e. the number of pole pairs is 1 pair), then the speed n=60*50/1=3000r/min.

Similarly, the synchronous speed of 4-pole, 6-pole and 8-pole motors is 1500, 1000 and 750.

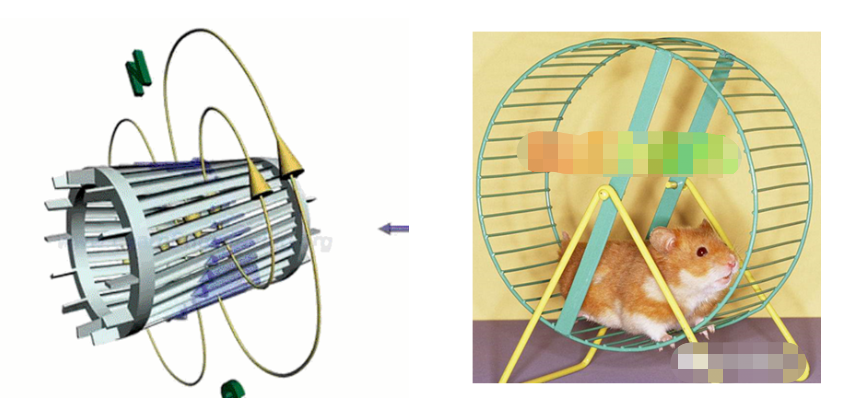

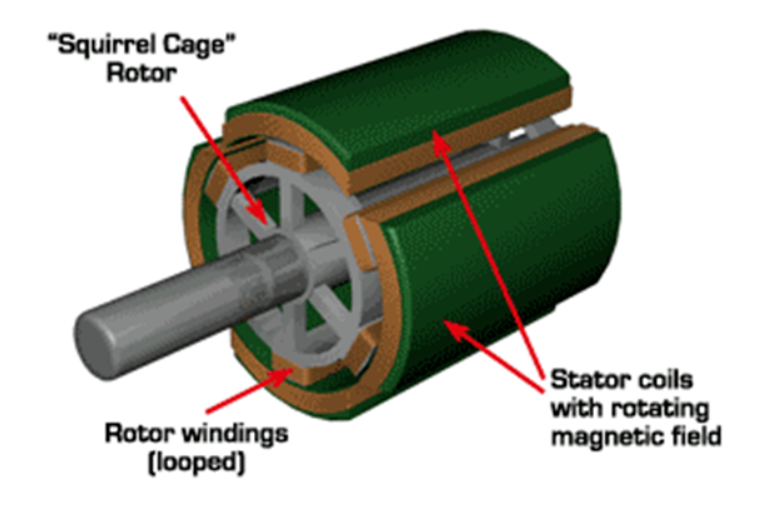

Asynchronous motors have a simple mechanism with a closed coil rotor, such as a squirrel cage type.

The rotor coil will cut the rotating magnetic field to generate the induced electric potential, which in turn generates the induced current, and finally the rotating magnetic field.

So that the rotor becomes an electromagnet and will follow the rotation of the stator magnetic field, so the rotor speed must be < the rotating magnetic field of the stator, so as to cut the magnetic induction lines.

The public number "Mechanical Engineering Digest", a refueling station for engineers!

That is, the asynchronous speed of the rotor <synchronous speed, there is a speed difference between the rotor and stator magnetic field, so it is called an asynchronous motor.

The rated speed of asynchronous motor varies slightly from manufacturer to manufacturer, about 2800+r/min for 2-pole motor, 1400+,950+,700+ for 4-pole, 6-pole and 8-pole asynchronous.

The speed of asynchronous motor is high when no load, and decreases when there is a load.

Asynchronous motor has simple structure, easy maintenance, reliable operation and cheap price, so it is widely used.

4. Three-phase AC motors - synchronous motors

Synchronous motor.

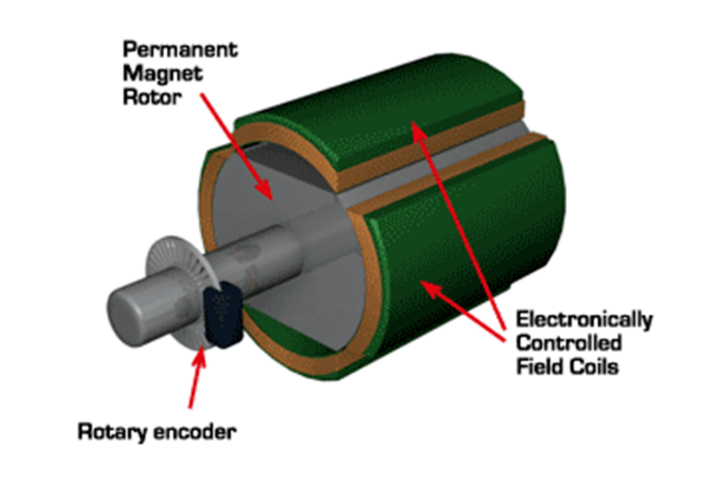

If you let the rotor speed = stator magnetic field rotation speed, it becomes a synchronous motor, at this time it is necessary to turn the stator into an electromagnet or permanent magnet, that is, to energize the stator, at this time no longer need to cut the magnetic induction line can rotate, the rotation speed and magnetic field rotation speed is the same, that is, the formation of synchronous motor.

Synchronous motor rotor structure is more complex than asynchronous motors, high prices, in production life is not as widely used as asynchronous motors, mainly used as generators, now thermal power stations, hydroelectric power stations, steam turbines, hydraulic turbines are basically synchronous motors.

5. Three-phase AC motor - asynchronous electric motors speed regulation

Asynchronous motor speed regulation: theoretically, asynchronous motor control AC frequency, voltage, or rotor resistance, motor pole distribution can be speed regulation, but in practice to achieve infinite speed regulation with the method of adjusting the frequency and voltage to achieve.

Because of the voltage regulation speed range is not large, generally can only be used in speed control requirements are not high occasions, the application is not widespread.

Variable frequency speed regulation: Speaking of frequency, we may have heard of it.

The full name of frequency conversion is Variable Voltage Variable Frequency (VVVF), which means that the voltage is changed when the frequency is changed, so that the speed range of asynchronous motor is large enough.

Frequency converters can be divided into two broad categories: AC-AC frequency converters and AC-DC frequency converters.

AC-DC inverter: AC power is directly transformed into AC power of another frequency by power electronics.

The maximum output frequency cannot exceed half of the input frequency, so it is generally used only in low speed, high capacity systems, and can eliminate the need for huge gear reducer.

AC-DC inverter will rectify the AC power into DC first, and then turn it into AC with controllable frequency and voltage through inverter, with PWM technology, this kind of inverter can realize a wide range of variable voltage and frequency.

For electric vehicles, the asynchronous motor is durable, strong overload capacity, and the control algorithm is so mature that it can be used completely.

6. Three-phase AC motor - speed regulation of synchronous motor

Synchronous motor speed regulation:

Synchronous machines have no turndown rate, and the control voltage cannot change the speed when the structure is determined, so before the appearance of frequency converters, synchronous motors were completely unregulated.

The appearance of frequency converter makes the AC synchronous motor also has a huge speed regulation range, because its rotor also has independent excitation (permanent magnet or electric excitation), its speed regulation range is wider than that of asynchronous motor, and the synchronous motor has been given a new life.

Synchronous motor variable voltage variable frequency speed control system can be divided into other-controlled variable speed control and self-controlled variable speed control.

For other-controlled variable frequency speed regulation, it is similar to the variable frequency regulation of asynchronous motor, which can be controlled by SVPWM and other control methods according to its mathematical model, and its performance is better than that of ordinary AC asynchronous motor.

Self-controlled inverter synchronous motor used to have a variety of names in the development process, such as commutatorless motor; when using permanent magnets and inputting three-phase sine wave, it can be called sine wave permanent magnet synchronous motor; and if inputting square wave, then it can be called trapezoidal wave permanent magnet synchronous motor, yes, it is similar to the previously said brushless DC machine (BLDM), we are not feeling a big circle of rap has turned Go back, but you must now have a deeper understanding of variable speed, so brushless DC motor when using DC input, but the use of synchronous motor frequency conversion technology (the same structure as the permanent magnet synchronous motor), in the Model3 on the use of DC brushless motor.

7. Single-phase AC asynchronous motor - single-phase AC series-excited motor (brush)

Single-phase AC series-excited motor, commonly known as series-excited motor or universal motor (UniversalMotor foreign name, named because of AC and DC universal), the armature winding and excitation winding are connected in series to work together.

Single-phase series-excited motor is also called AC-DC dual-use series-excited motor, which can work with either AC power or DC power.

The public number "Mechanical Engineering Literature", the refueling station for engineers!

The advantages of single-phase series-excited motor are that it has high speed, high starting torque, small size, light weight, not easy to block rotation, wide range of applicable voltage, and can be speed regulated by the method of voltage regulation, which is simple and easy to realize.

Therefore, it is widely used in power tools, such as angle grinder, hand drill, etc.

The structure of single-phase series-excited motor is very similar to that of DC series-excited motor, the main difference is that the stator core of single-phase series-excited motor must be made of silicon steel laminated, while the magnetic poles of DC can be made of both laminated and integral structure.

Single-phase series-excited motor speed regulation, most of the methods used to adjust the voltage, is to change the electric potential.

The voltage regulation method of single-phase series-excited motor uses controlled phase-shifting voltage regulation, which uses the trigger voltage of the SCR to lag behind the input voltage to achieve the phase-shifting trigger of the input voltage.

There are hardware and software methods in the implementation.

The regulated voltage method, using silicon controlled speed control technology, has a simple line, small size of components and other characteristics of a silicon controlled simple and effective method

(a) AC current variation curve;

(b) Rotation direction of the rotor when the current is positive half-wave

(c) Rotation direction of the rotor when the current is negative half-wave

8. Single-phase AC asynchronous motor - single-phase AC squirrel-cage motor (brushless)

Single-phase current through the armature winding produces a pulsating magnetic field rather than a rotating magnetic field, so single-phase asynchronous motors cannot be self-started.

To solve the starting problem, single-phase AC-powered asynchronous motors are often actually made to be two-phase.

The main winding is powered directly by the single-phase power supply; the secondary winding is spatially different from the main winding by 90° (electrical angle, equal to the mechanical angle divided by the number of motor pole pairs).

The secondary winding is connected to single-phase AC power supply after series connection of capacitor or resistor, so that the current passing through it and the current in the main winding have a certain phase difference.

This makes the synthetic magnetic field an elliptical rotating field, or perhaps even close to a circular rotating field.

The motor thus obtains starting torque.

The motor using resistance phase separation method is inexpensive, for example, the secondary winding can be wound with a thinner wire, but the phase separation effect is poor and energy is consumed in the resistance.

After the motor starts and reaches a certain speed, the secondary winding is usually removed automatically by a centrifugal switch mounted on the motor shaft to reduce the resistive losses and improve the operating efficiency.

It is generally used for the occasion that the starting torque requirement is not high, such as small lathe, small refrigerator, etc. The disadvantage is that the speed cannot be adjusted.

It is possible to make the synthetic magnetic field of the motor close to the circular rotating magnetic field at a certain working point of the motor, so as to obtain better working characteristics.

In order to make the split-phase asynchronous motor obtain better starting performance or better operating characteristics or both, the capacitance (amount of value) required is different and can be divided into three kinds

9. stepper motors - open-loop stepper motors

(Open-loop) stepper motors are open-loop controlled motors that convert electrical pulse signals into angular displacements, and are extremely widely used.

In the case of non-overload, the speed and stop position of the motor depends only on the frequency of the pulse signal and the number of pulses, and is not affected by changes in the load, when the stepper driver receives a pulse signal, it drives the stepper motor to rotate a fixed angle, called the "step angle", its rotation is to run at a fixed angle step by step. The rotation is run step by step at a fixed angle.

The number of pulses can be controlled to control the amount of angular displacement, so as to achieve the purpose of accurate positioning; at the same time, the pulse frequency can be controlled to control the speed and acceleration of motor rotation, so as to achieve the purpose of speed regulation.

Stepper motor is a kind of induction motor, which works by using an electronic circuit, i.e., a driver, to turn DC power into a time-sharing powered multi-phase timing control current.

Although stepper motors are powered by DC current, they cannot be understood as DC motors, which are power motors that convert DC electrical energy into mechanical energy, while stepper motors are open-loop control motors that convert electrical pulse signals into angular displacement.

10. Stepper motor - stepper servo comparison

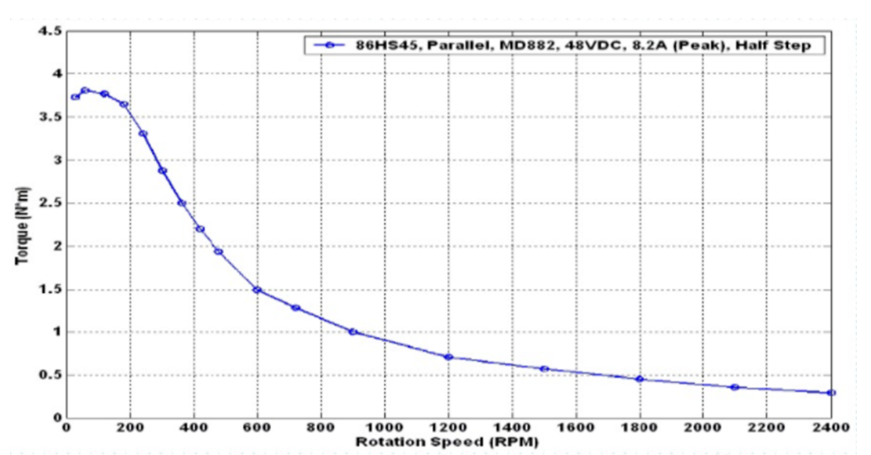

Note that stepper motors are used in low-speed applications - no more than 1000r/min per minute, the best working range is 150~500r/min, (closed-loop stepping up to 1500).

2 phase stepper motor at 60 ~ 70r/min is prone to low speed resonance phenomenon, generating vibration and noise, which needs to be avoided by changing the reduction ratio, increasing the fine fraction, adding magnetic dampers, etc.

Subdivision accuracy precautions, when the subdivision level is greater than 4, the accuracy of the step angle can not be guaranteed, high precision requirements, it is best to switch to more phases (i.e., smaller step angle) of the stepper motor or closed-loop stepper, servo motor.

(Open-loop) stepper motor and servo motor 7 different.

A control accuracy - servo motor control accuracy can be set according to the encoder, higher accuracy.

B low-frequency characteristics - stepper motors are prone to vibration at low frequencies, servo motors do not.

C moment-frequency characteristics - stepper motor torque becomes smaller with the increase in speed, so its maximum operating speed is generally in <1000r/min, servo motor in the rated speed (generally 3000r/min) can output the rated torque, in the rated speed above the constant power output, the maximum speed of up to 5000 r/min;.

D overload capacity - stepper motor can not be overloaded, servo motor maximum torque can be overloaded 3 times.

E operating performance - stepper motor for open-loop control, servo motor when closed-loop control.

F speed response - stepper motor start-up time 0.15 ~ 0.5s, servo motor 0.05 ~ 0.1, the fastest 0.01s to reach the rated 3000r / min.

G efficiency indicators - stepper motor efficiency of about 60%, servo motor about 80%.

In actual use will find: servo motor expensive, expensive out of many, so synchronous motors are more widely used, especially in the positioning accuracy requirements are not very high synchronous belt drive, flat belt conveyor and other occasions often use stepper motor.

11. Stepper motors - closed-loop stepper motors

Closed-loop stepper motors: In addition to open-loop stepper motors, there are stepper motors that have an encoder added to the end of the motor, allowing for closed-loop control.

Closed-loop control of stepper motors uses position feedback and/or velocity feedback to determine phase transitions appropriate to the rotor position, which can greatly improve the performance of stepper motors.

Servo systems without out-of-step phenomena.

Advantages of closed-loop stepper motors.

1. High speed response. Compared to suit motors, closed-loop stepper has very strong following of positioning commands, so the positioning time is very short. In the application of frequent start/stop, the positioning time can be significantly shortened.

2. Generate more torque than ordinary servo. Make up for the lack of step loss and low speed vibration of ordinary stepper system.

3. High torque can be generated even under 100% load, without loss of step operation, without considering torque loss and other problems like ordinary stepping systems.

4. By applying the closed-loop drive, the efficiency can be increased to 7.8 times, the output power can be increased to 3.3 times, and the speed can be increased to 3.6 times.

It can get higher running speed, more stable and smoother speed than open-loop control.

5. The stepper motor will be completely stationary when it stops, without the micro-vibration phenomenon of ordinary servo.

It can replace the application of general-purpose servo system when low cost and high precision positioning is required.

12. stepper motor - stepper closed-loop servo comparison

Closed-loop stepper motors automatically adjust the winding current size according to the size of the load, heat and vibration is less than open-loop stepper, there is encoder feedback so the accuracy is higher than ordinary stepper motors, motor response than open-loop stepper slower than servo motors faster, there is a position error during operation, the error will gradually decrease in milliseconds after the command stops.

High-speed torque than open-loop stepper, common applications in the 0-1500rpm occasion.

In summary: closed-loop stepper motor with low cost, high efficiency, no jitter, no stop micro-vibration, high rigidity, no rectification, high speed, high dynamic response, etc., is the replacement of high-cost servo systems, low-end open-loop stepper systems and other cost-effective solutions

13. Servo motor - General servo motor

Servo motor (servo motor), also called actuator motor, can make the control speed, position accuracy very accurate, can convert the voltage signal into torque and speed to drive the control object.

Unlike the principle structure of stepper motor, servo motor is a standard DC motor or AC induction motor because the control circuit is put outside the motor, and the motor part inside.

The servo motor relies on pulses for positioning. When the servo motor receives 1 pulse, it rotates by an angle corresponding to 1 pulse.

Every time the motor rotates an angle, the encoder will send out the corresponding number of feedback pulses. The feedback pulses and the pulses received by the servo driver form a closed-loop control, so that the servo driver can control the rotation of the motor very precisely to achieve precise positioning.

Servo motor control: Generally, servo motors for industrial use are controlled by three loops, namely current loop, speed loop and position loop, which can feedback the angular acceleration, angular speed and rotational position of the motor operation respectively.

The chip controls the drive current of each phase of the motor through the feedback of the three, so that the speed and position of the motor can run accurately as scheduled.

AC servo has the feature of constant torque under rated speed, common 200W,400W low and medium inertia AC servo rated speed is 3000rpm, the highest speed is 5000rpm, high speed.

The torque is proportional to the current, so it can work in the torque mode, such as locking screws, pressing terminals and other occasions that need constant torque.

AC servo work noise and vibration is very small, low heat generation.

The same volume of motor inertia rotor inertia is small, 400W servo inertia is only equivalent to the rotor inertia of 57 base 2NM stepper motor.

Servo has a short time overload capacity, the selection needs to consider the motor overload multiplier when acceleration and deceleration.

The servo uses closed-loop control and has the same position tracking error as a closed-loop stepper.

Servo requires commissioning before use.

The original torque of the stepper and servo motor is not enough, often need to work with the reducer, you can use the reduction gear set or planetary reducer.

6. Servo motor - servo

Servo is a class of DC servo motor, first used for small airplane models and now used for small robot joints.

From the structural analysis, a servo consists of a small DC motor, plus sensors, control chips, and reduction gear sets, which are mounted into an integrated housing.

It is able to control the rotation angle through an input signal (usually a PWM signal, but also a digital signal).

Since it is a simplified version, the original three-loop control of the servo motor is simplified to one loop, i.e., only the position loop is detected.

A cheap solution is a potentiometer, which is detected by a resistor, while an advanced solution will use a Hall sensor, or an encoder.

General servos are inexpensive and compact, but have very low accuracy and poor position calming capability, and can meet many low-end needs.

With the boom of consumer-grade small robots in the last two years, small and lightweight servos have instantly become the most suitable joint components.

However, robot joints require much higher performance than aerial servos, and as a commercial product also require much higher quality servos than DIY players.

Bem-vindo a compartilhar conosco mais informações sobre motores elétricos na área de comentários!

Qualquer dúvida sobre motor elétrico, entre em contato com o motor elétrico profissional fabricante em China do seguinte modo:

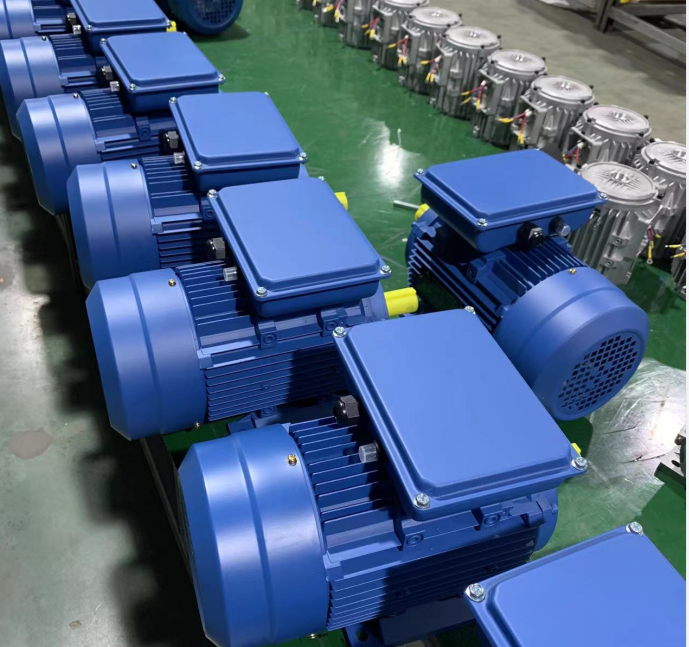

A Dongchun motor possui uma ampla gama de motores elétricos que são usados em vários setores, como transporte, infraestrutura e construção.

Obtenha uma resposta imediata.