Electric motor manufacturer

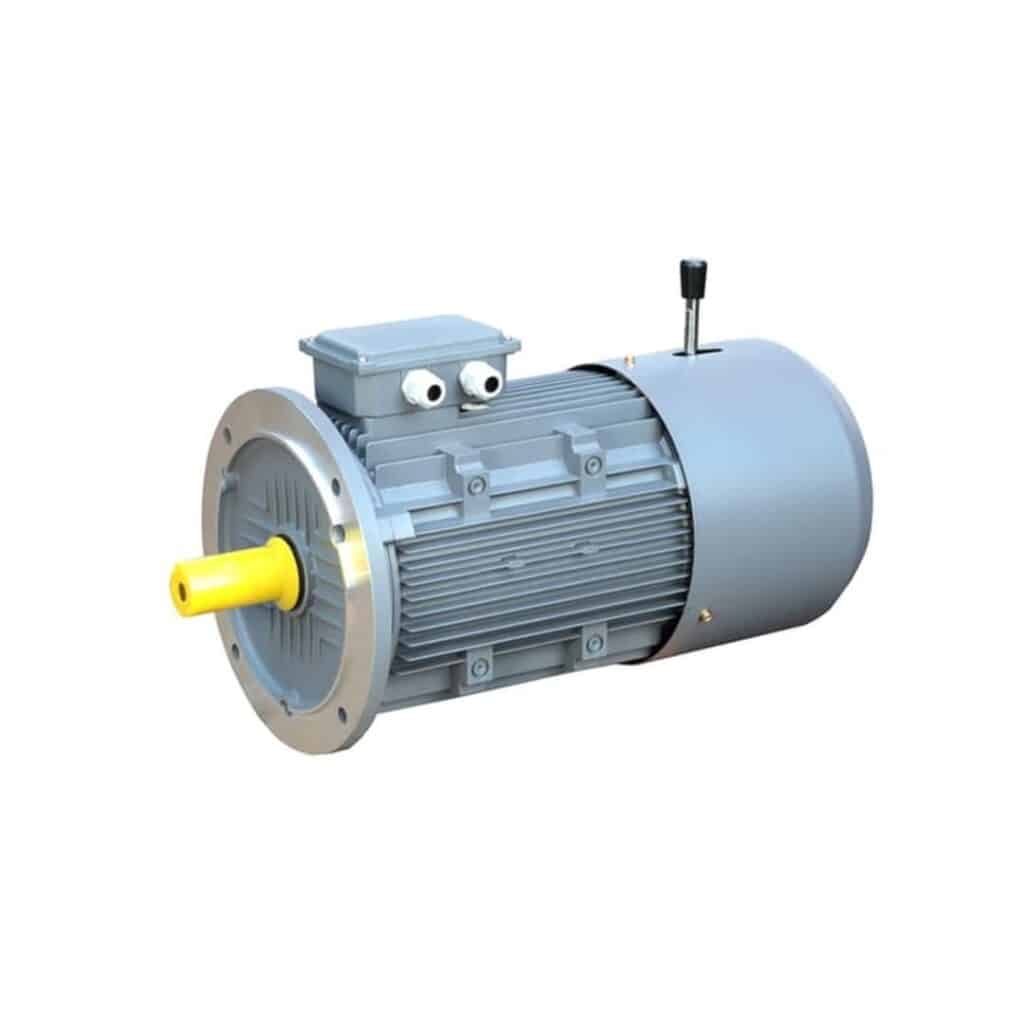

AC / DC BRAKE three phase motor

Dongchun is a electric motor manufacturer that offers many different three phase and single phase motor , Our electric motor factory in China. We are making both YEJA Series AC Electromagnetic braking three phase induction motor and YEJ2 Series DC Electromagnetic braking three phase induction motor.

The brake motor is a fully enclosed, self-cooling squirrel-cage type three-phase asynchronous motor with an additional disc-type DC brake, which has the advantages of rapid braking, simple structure, high reliability and high versatility. In addition, the brake has a manual release mechanism, and is widely used in various mechanical equipment and transmission devices that require fast stopping and accurate positioning.

The motor conforms to JB/T64561992 standard, and this series of motor is widely used in metal processing machine tools, packaging machinery, woodworking machinery, food machinery, chemical machinery, textile machinery, construction machinery, etc.

Insulation grade: F. Protection grade: F. Insulation grade: B/F, protection grade: IP55.

YEJA- AC Brake motor

Frame: 63-180

Power: 0.12kW /0.16Hp to 22kW/30Hp

Pole: 4 pole, 6 pole, 8,pole

Service factor: S1

Voltage: 220/380V, 230V/440V, 380/660V,400/690V, 50/60Hz

YEJ2- DC Brake motor

Frame: 80-225

Power: 0.75kW /1Hp to 45kW/60Hp

Pole: 2 pole, 4 pole, 6 pole, 8,pole

Service factor: S1

Voltage: 220/380V, 230V/440V, 380/660V,400/690V, 50/60Hz

Request a quote for more detailes

All you need to know about Brake motorr

The DC disc brake of the brake motor is mounted on the end cover of the motor at the non-shaft extension. When the brake motor is connected to the power supply, the brake motor also works at the same time. When the power supply is cut off, the brake motor electromagnet loses its magnetic suction and the spring pushes the armature against the brake disc, which immediately stops the brake motor under the action of the frictional torque.

Brake motors are widely used in various mechanical equipment and transmission devices that require fast stopping and accurate positioning. The brake motor conforms to the JB/T6456-1992 standard and is widely used in metal processing machine tools, packaging machinery, woodworking machinery, food machinery, chemical machinery, textile machinery, construction machinery and gear reducers.

What are the YEJA Series AC Electromagnetic braking three phase motor used for ?

Electric motors are used in a wide range of machinery and equipment with no special requirements

Frame: 63-180 , Power: 0.12kW /0.16Hp to 22kW/30Hp, Pole: 4 pole, 6 pole, 8,pole, 50Hz/60Hz

- Metalworking machine tools, packaging machinery,

- woodworking machinery, food machinery,

- chemical machinery, textile machinery

- construction machinery and gear reducers etc.

What are YEJ2 Series DC Electromagnetic braking three phase motor used for ?

Electric motors are used in a wide range of Automated production equipment and equipment with no special requirements

Frame: 80-225 , Power: 0.75kW /1Hp to 45kW/60Hp, Pole: 2 pole, 4 pole, 6 pole, 8,pole, 50Hz/60Hz

- Metalworking machine tools, packaging machinery,

- woodworking machinery, food machinery,

- chemical machinery, textile machinery

- construction machinery and gear reducers etc.

Wanna detailed informtaion for brake motors

The Process Flow & Duration Estimation

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking 1*20ft container of products:

Step 1 : Pay the deposit (1-3days)

Once the order is confirmed, the production will be arranged as soon as the deposit from customer .

Step 1 : make the motor's technical design (1-3 days)

The elelctric motor ‘s techincal data will be designed as customer requirements for the data of voltage, Frequency , power, frame …ect.

Step 3: testing sample for special techinical date motor (within 3-7 days)

For the electric motors with special parameters, we will make sample for pre-testing before mass production to ensure that there are no problems.

Step 4: Bulk Manufacturing (20-30 days)

For bulk production, a lead time of 20-30 days is usually required from the purchase of raw materials to the 100% testing of finished electric motors.

Step 5: Shipping (5-7 days)

Once the goods are ready , we will inform the customer to arrange for the balance and upon receipt of the balance arrange for the booking of the shipment.

Want to know how to compress lead times?

Please tell us what you need and our engineers will give you a professional solution。

Request A Free Quote

We'd like to work with you!

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right electric motor you want.

+86-159 6700 7958

All uploads are secure and confidential.