Our after-sales team received a typical failure of a customer's electric motor with a broken shaft, which occurred at the root of the shaft extension.

According to years of experience, the initial analysis of the customer's operating conditions are special, and it is likely to use the pulley dragging.

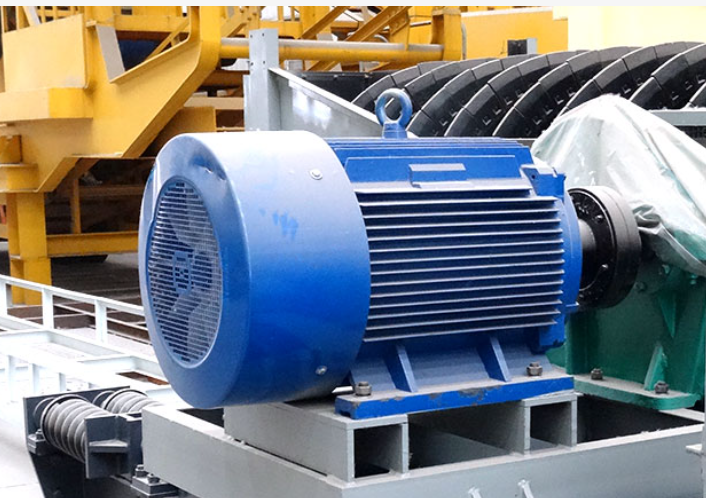

The later understanding of the situation is basically consistent with the analysis and inference; the electric motor is an H355 8-pole motor with 160kW power, and the customer used a pulley to drag the crusher.

From the analysis of the situation of motor force, any motor manufacturer does not recommend the customer to use belt drive, especially for dragging crushing equipment.

Electric motor using belt drive problem lead to the motor shaft break

For the electric motors using the belt pulley coupling, when some customers to the motor output shaft with pulley.

If the pulley is too heavy or belt installation is too tight.

It will also lead to the electric motor in the process of operation, the electric motor output bearing subject to continuous alternating bending stress, this stress on the bent shaft to produce bending moment maximum in the output motor drive shaft bearing pivot point near the repeated impact caused by fatigue, so that the shaft gradually produce cracks, and eventually completely fracture.

In general, large motors should avoid using pulley drive as far as possible.

The technical conditions of the electric motors and specification manufacturers' manuals are specified, for H280 and above electric motors are not recommended to use pulley drive.

The reason or theoretical basis is just mentioned:

the belt drive itself makes the electric motor shaft in the normal load at the same time, will be additional bending stress, plus the belt is too tight factors, resulting in the electric motor body in the operation of the shaft is always subject to large alternating load, and machine shafts extension and bearings.

The electric most serious problem of stress concentration in the part, easy to lead to broken shaft failure.

If the new motor is not centered with the equipment it is towing, the motor shaft will be subjected to additional or additional alternating loads beyond the design expectation, which will cause fatigue damage to the motor shaft metal during the motor operation.

When the motor shaft extension or the relative weak link of the shaft is subjected to the additional load is too large.

It will cause the motor shaft to have bending deformation in the radial direction, which is more terrible to further deteriorate the motor shaft operating conditions, and the combined effect of the load torque, eventually leading to the motor shaft fracture.

The fracture position is generally in the place near the bearing, mostly in the inner position of the end cover.

Crusher classification and introduction to avoid the motor failure

● Box Crusher

Box crusher (square box broken) is commonly known as square box crusher and heavy hammer crusher.

It is suitable for crushing various minerals of brittle materials.

crushed materials are coal, salt, baiya, gypsum, alum, brick, tile, limestone, lime stone, shale, coal gangue, etc..

The compressive strength of the material does not exceed 300 MPa and the humidity is not more than 30%.

● Jaw Crusher

Jaw crusher is commonly known as jaw crusher, also known as tiger mouth.

It is a crusher with two jaws, the movable jaw and the static jaw, forming a crushing chamber, simulating the movement of two jaws of an animal to complete the crushing operation of materials.

is widely used in mining and smelting, building materials, highways, railroads, water conservancy and chemical industries to crush various ores and large materials, such as river pebbles, granite, basalt, quartzite, iron ore, pyrochlore, sandstone production line limestone, calcite, dolomite, barite, talc, gypsum, bentonite, etc.

Find professional electric motor manufacturer to get a free Quote

Dongchun motor China here

እባክዎን በደግነት ምርቶቹን እንደሚከተለው ያረጋግጡ

ነጠላ ደረጃ ሞተርYC፣ YCL ከብረት ብረት ጋር እና ML፣ የእኔ ሞተር ከአሉሚኒየም አካል ጋር

የሶስት ደረጃ ሞተር : IE1፣ IE2፣ IE3 ሞተር ለሁለቱም የብረት ብረት አካል እና ለአሉሚኒየም አካል

የብሬክ ሞተርየዲሲ ብሬክ ሞተር እና ኤሲ ብሬክ ሞተር

ሞተርሳይክል VFDr: ድግግሞሽ ተለዋዋጭ ድራይቭ ሞተሮች.

ከዶንግቹን ሞተር ነፃ ዋጋ ያግኙ