Torque is the basic form of load on the drive shaft of various working machines.

It is closely related to the working capacity, energy consumption, efficiency, operating life, and safety performance of power machines.

As a typical power machine, torque is a very important performance parameter for electric motors.

Different working conditions require different torque performance for electric motors.

For example, wire-wound rotor ac motor, high-rotation ac motors, common cage induction motors, and frequency-controlled motors.

The torque setting of the ac motors is all about the load, and different load characteristics have different requirements for the torque characteristics of the induction motor.

The torque of the motor mainly includes the maximum torque, minimum torque and starting torque.

The starting torque and minimum torque and the ability of the industrial motors to cope with the changing load resistance torque during the starting process are considered, involving the starting time and starting current, and are reflected in the form of accelerating torque.

The maximum torque is more often a reflection of the motor's overload capability during operation.

Starting torque is one of the important technical indexes to measure the motor starting performance.

The larger the starting torque is, the faster the electrical motors accelerates, the shorter the starting process is, and the more it can start with heavy load.

These all indicate good starting performance.

On the contrary, if the starting torque is small, it is difficult to start and the starting time is long, so that the three phase motor winding is easy to overheat and even can't start with heavy load.

The maximum torque is an important technical index to measure the short time overload capacity of the ac motors.

The larger the maximum torque is, the greater the motor's ability to withstand mechanical load shock.

If the asynchronous motor is overloaded for a short time while running with load, when the maximum torque of the ac motor is less than the overload resistance torque, the motor will stop and block and burn, which is often referred to as overload fault.

Minimum torque is the minimum torque motor in the process of conventional motor starting.

It is the minimum value of steady-state asynchronous torque produced by the motor between zero speed and the corresponding maximum speed at rated frequency and rated voltage.

When it is less than the load resistance torque in the corresponding state, the three phase induction motor speed will stall in the non-rated speed state and cannot be started.

In view of the above analysis, we can conclude that the maximum torque is more often a manifestation of the motor's ability to resist overload during operation.

While the starting torque and the minimum torque are two specific conditions of the high efficiency motor starting process.

Different series of induction motor, depending on the corresponding operating conditions, have some different choices for the design of torque, the most common are ordinary cage motors, high torque motors for special loads, and wound rotor motors.

Ordinary cage motor is normal torque characteristics (N design), generally for continuous working system, there is no problem of frequent starting, but requires high efficiency and low rate of rotation. The current IE2, IE3, IE4, and other high-efficiency motors are the representatives of ordinary cage motors.

When starting a wound rotor motor, the starting current can be better controlled by connecting the starting resistor in series with the collector ring system, and the starting torque is always close to the maximum torque, which is one of the reasons for its better application.

Some special working conditions of the load, the motor is required to have a larger torque.

We also talk about H design motor, in the previous topic we talked about forward and reverse motors, constant resistance loads where the load resistance torque is basically constant at the rated torque, impact loads with high rotational inertia, winding loads requiring softer torque characteristics, etc.

For motor products, torque is only one aspect of its performance parameters, in order to optimize the torque characteristics.

It may be necessary to sacrifice the performance of other parameters, especially with the dragged equipment is very important to match, systematically analyze and optimize the comprehensive operation effect, more conducive to the optimization of the conventional motorS body parameters and achieve, system energy saving has also become a common research topic for many motor manufacturers and equipment manufacturers.

Find TOP professional electric motor manufacturer in China,

All these faults will lead to abnormal motor power supply and feedback.

It is a very important to find a professional electric motor manufacturer to save the time.

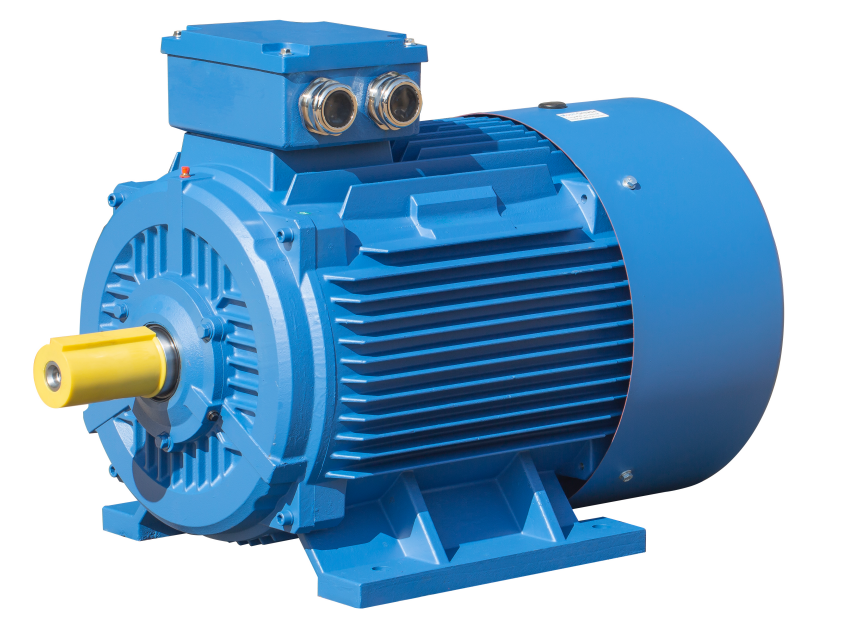

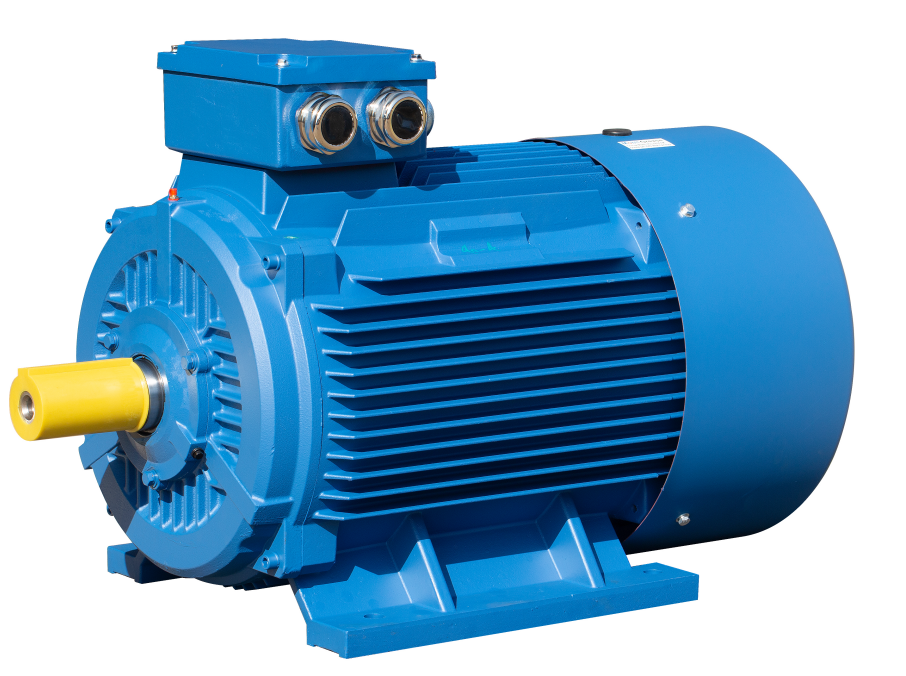

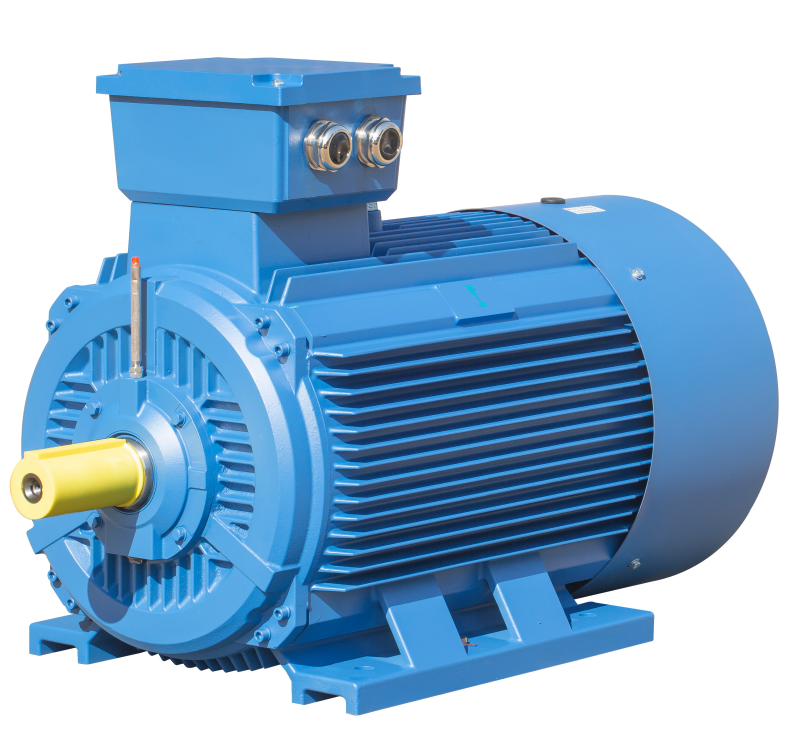

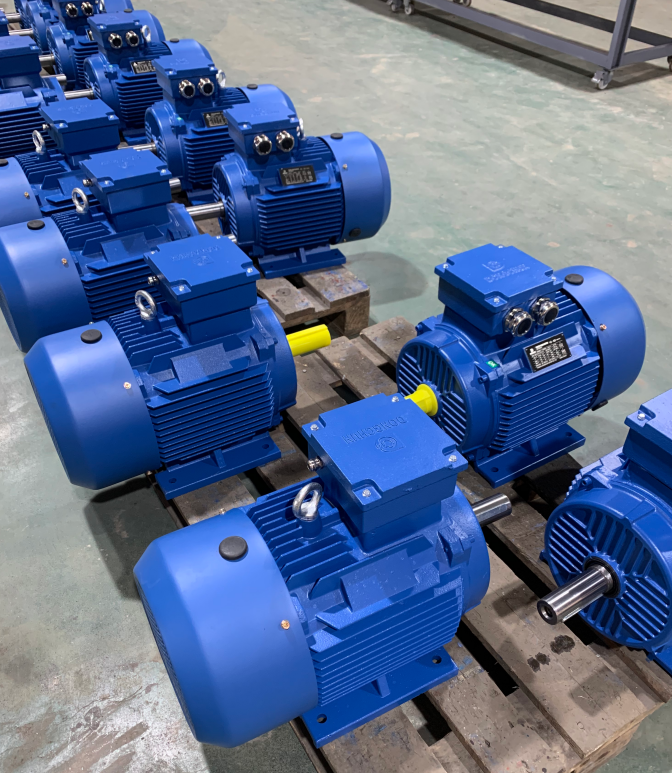

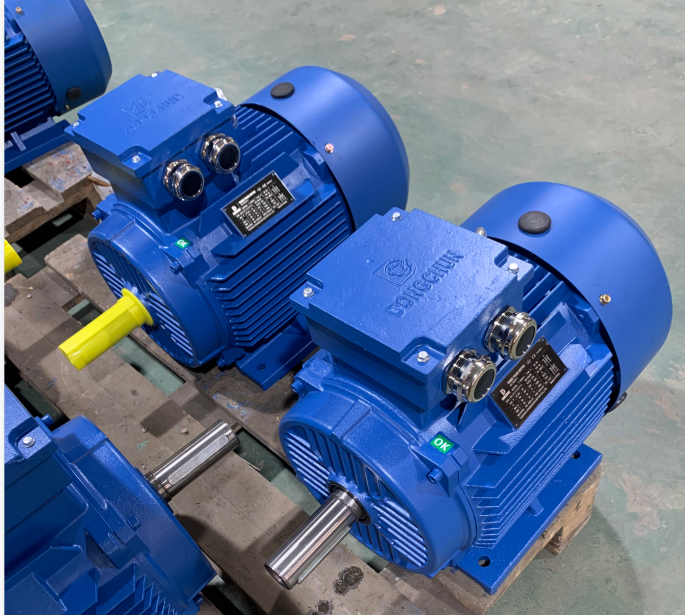

Dongchun motor is a professional manufacturer of electric motors in China.

Please kindly check the products as follows

single phase motor: YC, YCL with cast iron body and ML , MY motor with Aluminium body

Three phase motor : IE1, IE2, IE3 motor for both cast iron body and Aluminium body

Brake motor: DC brake motor and AC brake motor

VFD motor : frequency variable drive motors.

Get a Free quote from Dongchun motor