Electric Motors are usually used with many different equipment in the workplace.

Today, let's talk about the motor with belt drive system.

If you are interested, you can read the manual of the motor products, most of the manual, for the electric motor and equipment docking method will put forward specific requirements, to ensure that the electrical motor and equipment are coaxial, and to try to reduce the shaft is subject to radial force perpendicular to the axis.

Therefore, for the transmission of the motor, it is more recommended to use couplings, and not recommended to use the belt drive, especially for high-power motors, the belt drive system will be too tight because of the synchronous belt, pulley diameter is too large, and other factors, resulting in unnecessary broken shaft problems.

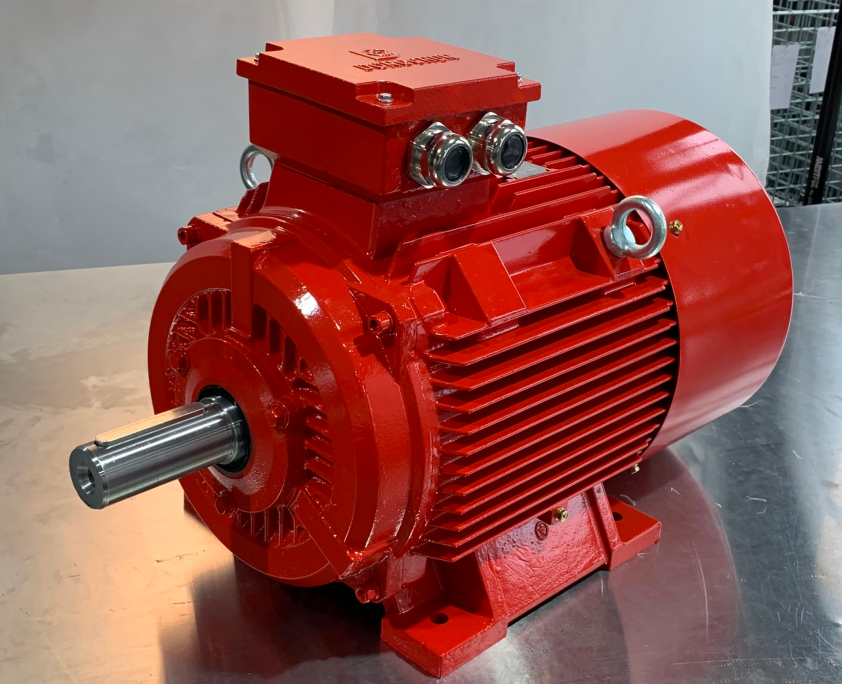

In order to avoid the problem of broken shaft of electric motor, the electric motor manufacturer will have the necessary control over the material quality of electric motor shaft, processing technology, and the design of the shaft, but for the user of the electric motor, the necessary communication should be made with the electric motor manufacturer for the specific installation.

If the same problem occurs on the same product, or the same problem occurs only on the same customer, it is necessary for us to make a full analysis of such problems, and the supply and demand sides to solve the substantive problems through deep communication.

How to choose the electric motor?

When choosing an electric motor as a power machine, the main thing is to determine the type and specification of the electric motor, in order to make the energy savings.

To choose the type of electric motor, we need to consider the load characteristics of the working machine, production process requirements, operating environment and power supply conditions of the grid.

The main principle to determine the electric motor specification is to check the heat generation, starting torque and overload torque of the electrical motor according to the production process and load conditions.

If the production process does not require speed adjustment, AC induction motor should be considered first:

if the load is smooth, general squirrel-cage asynchronous motor can be used;

if the machine needs to start under heavy load, squirrel-cage asynchronous motor with high starting torque or wire-wound asynchronous motor can be used.

Many work machines require speed adjustment with power transmission belts, some only need electric motor for a few stages of speed regulation, such as machine tools, etc., can use multi-speed AC asynchronous motor.

Electric Motor starting method

There are two types of motors: direct start and voltage reduction start.

For squirrel-cage asynchronous motor, direct starting should be preferred.

However, when starting directly, the starting current usually reaches 4-7 times of the rated current, while the starting torque is only 0.8-1.5 times of the rated torque, and due to the high starting current, the grid capacity must be considered.

There are three methods of voltage reduction starting.

● Resistor or reactor voltage reduction.

A resistor or reactor is connected in series with the stator winding during starting, and then shorted out after starting.

In this method, the starting current is reduced to 1/K times, but the starting torque is reduced to 1/K2 times.

● Star-delta voltage reduction.

Temporarily connect the stator winding to star when starting, and then change the stator winding to triangle after starting.

This method is only applicable to the motor whose stator winding is connected in triangle during normal operation,

which can reduce the grid current to 1/3 of the direct starting and the starting torque to 1/3 accordingly.

●Autotransformer voltage reduction.

When the motor is started, the autotransformer is used to supply power to the motor so that the motor voltage is reduced to 1/K of the rated voltage, and then the autotransformer is removed after starting and the motor is connected to the grid directly.

In this way, the grid current and torque will be reduced to 1/K2 of the direct starting.

Reduced voltage starting is only suitable for driving lighter loads.

If you want to limit the starting current and have a large starting torque,

you must use a wire-wound asynchronous motor, connect a starting resistor in series with the rotor winding circuit, and remove the resistor step by step during the starting process.

In order to simplify the starting equipment and improve the starting characteristics, frequency sensitive varistor is often used instead of starting varistor.

For DC motors, except for small capacity, direct starting is generally not allowed,

in order to limit the current must be connected in the armature circuit starting resistance.

To get more information about electric motors,

Please check from the electric motor manufacturer as below ;

Get a free quote from Dongchun motor