About the electric motor, we often have a lot of different questions, today I summarize TOP 13 questions about the electric motor together, also welcome to add more;

Why does the electric motor generate shaft current?

The current in the motor's shaft - bearing housing - base circuit is called shaft current.

Shaft current is generated because of.

(1) magnetic field asymmetry.

(2) harmonics in the supply current.

(3) poor manufacturing and installation, uneven air gap due to rotor eccentricity.

(4) detachable stator core with gaps between the two semicircles.

(5) there is a sector stacked stator core of the number of pieces of patchwork selection is not appropriate.

Hazards.

Make the motor bearing surface or ball erosion, shape course point microporous, so that the bearing running performance deterioration, friction loss and heat generation increase, and eventually cause bearing burn.

Prevention.

(1) eliminate pulsating flux and power harmonics (such as the addition of AC reactor on the output side of the inverter).

(2) motor design, the sliding bearing seat and base insulation, rolling bearing outer ring and end cover insulation.

why the general motor can not be used in highland areas?

Altitude on the motor temperature rise, motor corona (high-voltage motor) and DC motor commutation have a negative impact.

The following three aspects should be noted.

(1) high altitude, the greater the temperature rise of the electric motor, the smaller the output power. But when the temperature rises with the altitude and decreases enough to compensate for the effect of altitude on temperature rise, the rated output power of the motor can be unchanged.

(2) high-voltage electric motor in the plateau use to take anti-corona measures.

(3) altitude is not good for DC electric motor commutation, pay attention to the choice of carbon brush material.

why should not the electric motor light load operation?

When the electric motor is running at light load, it will cause.

(1) the motor power factor is low.

(2) motor efficiency is low.

It will cause equipment waste and uneconomical operation.

What are the causes of electric motor overheating?

(1) excessive load.

(2) lack of phase.

(3) air duct blockage.

(4) low speed running time is too long.

(5) power harmonics are too large.

What do you need to do before putting the motor into use for a long time?

(1) measurement of the stator, winding between each phase and winding to ground insulation resistance.

Insulation resistance R should meet the following formula.

R>Un/(1000+P/1000)(MΩ)

Un: rated voltage of motor winding (V)

P: motor power (KW)

For the motor with Un = 380V, R>0.38MΩ.

If the insulation resistance is low, it can be.

a: no-load operation of the electric motor for 2 to 3h drying.

b: using 10% of the rated voltage of low-voltage alternating current into the winding or three phase winding in series with DC baking, keeping the current at 50% of the rated current.

c: use the fan to send in hot air or heating element heating.

(2) Clean the electric motor.

(3) Replace the bearing grease.

Why can't you start the electric motor in cold environment arbitrarily?

The electric motor in the low temperature environment for too long, will.

(1) electric motor insulation cracking.

(2) bearing grease freeze.

(3) wire connector solder pulverization.

Therefore, the motor in the cold environment should be heated and preserved, and the windings and bearings should be checked before operation.

the electric motor three-phase current unbalance what are the causes?

(1) three-phase voltage imbalance.

(2) a phase within the electric motor branch is poorly welded or poor contact.

(3) Electric motor winding turns short circuit or short circuit to ground, phase to phase.

(4) Wiring errors.

why 60Hz electric motor can not be used connected to 50Hz power supply?

The electric motor is generally designed to make the silicon steel sheet work in the magnetization curve of the satiation area, when the supply voltage is certain, reduce the frequency will increase the flux, excitation current, resulting in increased motor current, increased copper consumption, and ultimately lead to higher motor temperature, and in serious cases may also burn the motor due to coil overheating.

What are the causes of electric motor phase loss?

For power supply.

(1) poor contact with the switch.

(2) transformer or line disconnection.

(3) insurance fuse.

Electric Motor.

(1) motor junction box screws loose poor contact.

(2) internal wiring poor welding.

(3) motor winding disconnection.

What are the causes of abnormal vibration and sound of the motor?

Mechanical aspects.

(1) poor bearing lubrication, bearing wear.

(2) loose fastening screws.

(3) there are debris in the motor.

Electromagnetic aspects.

(1) electric motor overload operation.

(2) three-phase current imbalance.

(3) phase loss.

(4) stator, rotor winding short-circuit fault.

(5) cage rotor welding part of the open welding caused by broken bars.

What do you need to do before starting the motor?

(1) measurement of insulation resistance (for low voltage electric motors should not be less than 0.5MΩ).

(2) measure the power supply voltage. Check whether the electric motor wiring is correct and whether the power supply voltage meets the requirements.

(3) check whether the starting equipment is good.

(4) check whether the fuse is appropriate.

(5) check whether the electric motor grounding, and zeroing is good.

(6) check whether there are defects in the transmission device

(7) check whether the electric motor environment is suitable, and remove flammable materials and other debris.

What are the causes of electric motor bearing overheating?

electric Motor itself.

(1) bearing inner and outer ring with too tight.

(2) the shape tolerance of parts have problems, such as the seat, end cover, shaft and other parts coaxiality is not good.

(3) improper selection of bearings.

(4) bearing lubrication or bearing cleaning is not clean, there are debris in the grease.

(5) shaft current.

In use.

(1) improper installation of the unit, such as the coaxiality of the motor shaft and the shaft of the device being towed is one with the requirements.

(2) Belt pulley pulling too tightly.

(3) poor bearing maintenance, insufficient grease or beyond the use period, dry and deteriorated.

What are the causes of low insulation resistance of the electric motor?

(1) winding moisture or water intrusion.

(2) dust or oil accumulation on the winding.

(3) insulation aging.

(4) electric motor leads or terminal board insulation damage.

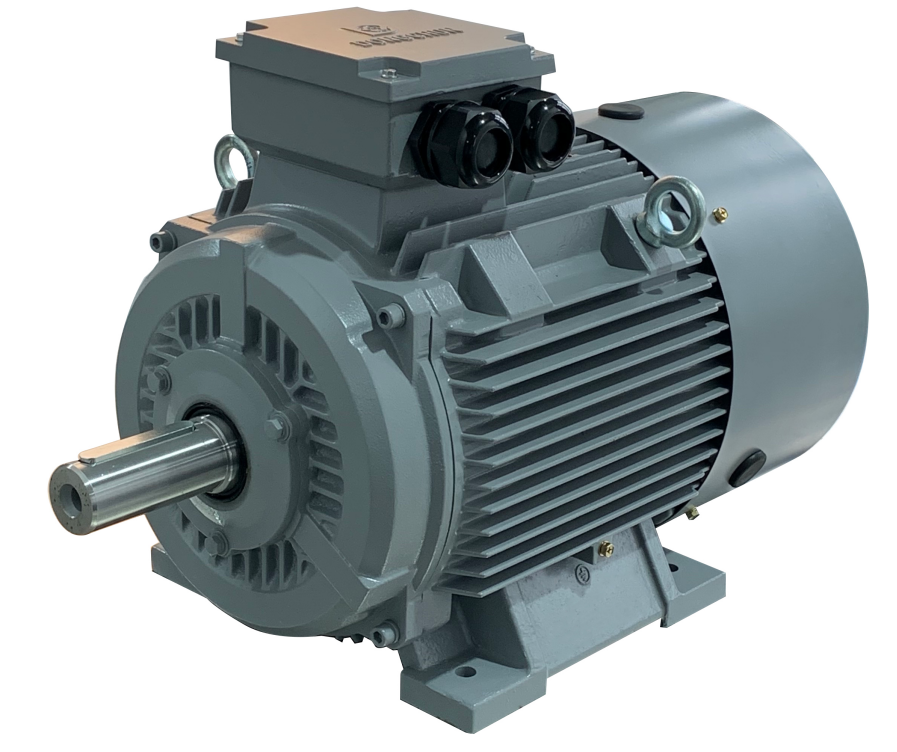

Dongchun motor is a professional manufacturer of electric motors in China.

Please kindly check the proudcts as follows

single phase motor : YC, YCL with cast iron body and ML , MY motor with Aluminium body

Three phase motor : IE1, IE2, IE3 motor for both cast iron body and Aluminium body

Brake motor: DC brake motor and AC brake motor

VFD motor : frequency variable drive motors.

If you would like to make a professional order, please kindly send us an inquiry.

Dongchun motor has a wide range of electric motors that are used in various industries such as transportation, infrastructure, and construction.

Get a prompt reply.