What is the difference between VFD motors and normal three phase motors? how to select VFD motor ?

I have checked a lot of information, but I think it is not complete, today I have compiled some information, you can learn about this knowledge together.

Difference between VFD motor and normal IEC three phase motor?

Frequency converter is an electrical energy control device that uses the on-off action of power semiconductor devices to convert the industrial frequency power supply to another frequency.

The inverter we use now mainly adopts the AC-direct-AC method (VVVF inverter or vector-controlled inverter), which first converts the AC power at the working frequency into DC power through a rectifier, and then converts the DC power into AC power with controllable frequency and voltage to supply the motor.

The circuit of the inverter is generally composed of four parts: rectifier, intermediate DC link, inverter and control.

The rectifier is a three-phase bridge type uncontrollable rectifier, the inverter is an IGBT three-phase bridge type inverter with PWM waveform output, and the intermediate DC link is for filtering, DC energy storage and buffering reactive power.

Inverter selection.

Inverter selection should determine the following points.

1) The purpose of using frequency conversion; constant voltage control or constant current control, etc.

2) The type of load of the inverter; such as vane pump or displacement pump, etc.

Pay special attention to the performance curve of the load, the performance curve determines the way and method of application.

3) Matching problem of inverter and load.

Voltage matching; the rated voltage of the inverter matches the rated voltage of the load.

Current matching; for ordinary centrifugal pumps, the rated current of the inverter matches the rated current of the motor. For special loads such as deep water pumps

It is necessary to refer to the motor performance parameters to determine the inverter current and overload capacity with the maximum current.

Torque matching; this situation is possible with constant torque loads or with reduction devices.

4) When using an inverter to drive a high-speed motor, the output current value increases due to the increase in high harmonics as a result of the small reactance of the high-speed motor.

Therefore, the selection of the inverter used for high-speed motors has a slightly larger capacity than the selection of ordinary motors.

5) If the inverter is to run a long cable, then measures should be taken to suppress the impact of the long cable on the ground coupling capacitance to avoid the inverter output power shortage.

so in such cases, the inverter capacity should be enlarged by one grade or the output reactor should be installed at the output of the inverter.

6) For some special applications, such as high temperature, high altitude.

this will cause the inverter capacity reduction, inverter capacity should be enlarged by one gear.

How to select the VFD Frequency Variable Motor?

VFD Frequency Variable Motor are generally selected from 4-stage motors, the base frequency operating point is designed at 50Hz, frequency 0-50Hz (speed 0-1480r/min) range of motors for constant torque operation, frequency 50-100Hz (speed 1480-2800r/min) range of motors for constant power operation, the entire speed range (0-2800r/min).

Basically meet the General drive equipment requirements, its operating characteristics and DC speed control motor, smooth and stable speed regulation.

If you want to increase the output torque in the constant torque range, you can also choose a 6-stage or 8-stage motor, but the size of the motor is relatively larger.

As the electromagnetic design of the frequency-controlled motor uses flexible CAD design software.

The design point of the motor's fundamental frequency can be adjusted at any time, and we can accurately simulate the motor's working characteristics at each fundamental frequency point on the computer, which also expands the motor's constant torque speed range, and according to the actual working conditions of the motor.

We can make the motor's power bigger in the same seat number, and also in The output torque of the motor can be increased on the basis of the same inverter to meet the design and manufacture of the motor in the best condition under various working conditions.

Frequency conversion motors can be equipped with additional speed encoders to achieve the advantages of high precision speed and position control and fast dynamic response.

DC (or AC) brake can also be used to achieve fast, effective, safe and reliable braking performance.

Variable frequency speed motor adjustable base frequency design, we can also manufacture a variety of high-speed motor, in high-speed operation to maintain the characteristics of constant torque, to a certain extent to replace the original medium frequency motor, and low price.

Frequency conversion motor for three-phase AC synchronous or asynchronous motor, according to the inverter output power supply has three phase 380V or three phase 220V, so the motor power supply also has three phase 380V or three phase 220V different differences.

Generally below 4KW inverter only three phase 220V can, because the frequency conversion motor is to motor base frequency point (or inflection point) to divide the different constant power speed control area and constant torque speed control Zone.

So the inverter base frequency point and the setting are very important.

Why IEC three phase motors can not be used as VFD motor ?

Many customers who repair inverters ask whether ordinary motors with inverters are inverter motors?

It is true that ordinary motor with inverter can realize inverter operation, but it is not a real inverter motor.

In fact, the ordinary motor is designed by constant frequency and constant voltage, and it is impossible to fully adapt to the requirements of inverter speed regulation, so it can't be used more as inverter motor.

The impact of inverter on the motor is mainly in the motor efficiency and temperature rise

The frequency converter can produce different degrees of harmonic voltage and current in operation, making the motor run under non-sinusoidal voltage and current, the high harmonics inside will cause the motor stator copper consumption, rotor copper consumption, iron consumption and additional loss increase, the most significant is the rotor copper consumption, these losses will make the motor extra heat, reduce efficiency, reduce the output power, the ordinary motor temperature rise is generally increased by 10% -20%. -20%.

Insulation strength of the motor

The frequency converter carrier frequency is from several thousand to more than ten thousand Hz, which makes the motor stator winding to bear a high voltage rise rate, which is equivalent to applying a steep shock voltage to the motor, making the inter-turn insulation of the motor bear a more serious test.

Harmonic electromagnetic noise and vibration

When ordinary motor adopts inverter power supply, it will make the vibration and noise caused by electromagnetic, mechanical and ventilation factors become more complicated. The various harmonics contained in the inverter power supply interfere with each other and form various electromagnetic excitation forces with the inherent space harmonics of the electromagnetic part of the motor, thus increasing the noise. Due to the wide operating frequency range of the motor (public number: pump housekeeper) and the wide range of speed changes, it is difficult to avoid the frequency of various electromagnetic force waves from the inherent vibration frequency of each structural part of the motor.

The cooling problem at low speed

When the power frequency is low, the loss caused by the high harmonics in the power supply is larger; secondly, when the speed of the variable motor decreases, the cooling air volume decreases proportionally to the third power of the speed, resulting in the heat of the motor not being dissipated, the temperature rise increases sharply, and it is difficult to realize the constant torque output.

The above is my summary of some knowledge, if you have anything to add, welcome to leave a message in the comments section.

Dongchun motor is a professional manufacturer of electric motors in China.

Please kindly check the proudcts as follows

single phase motor : YC, YCL with cast iron body and ML , MY motor with Aluminium body

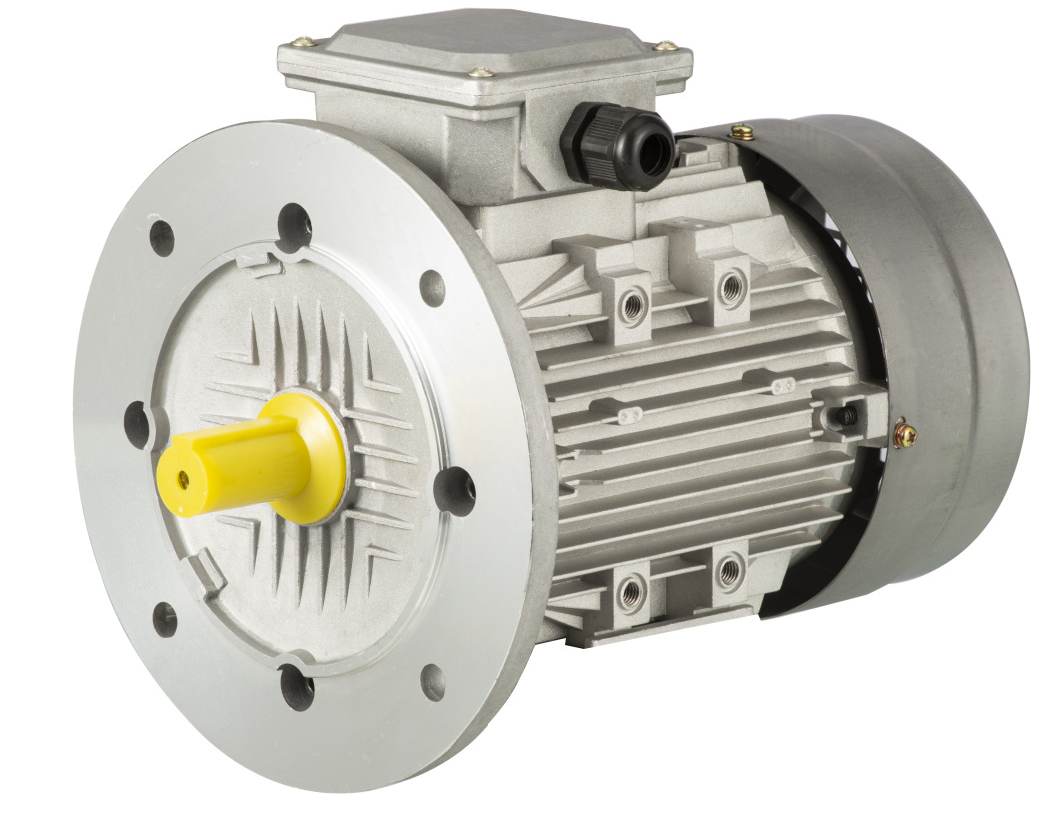

Three phase motor : IE1, IE2, IE3 motor for both cast iron body and Aluminium body

Brake motor: DC brake motor and AC brake motor

VFD motor : frequency variable drive motors.

If you would like to make a professional order, please kindly send us an inquiry.

Dongchun motor has a wide range of electric motors that are used in various industries such as transportation, infrastructure, and construction.

Get a prompt reply.