Compared to the variable frequency drive motor, the main feature of the variable frequency drive motor is the variability of the control motor speed, variable speed motor is the frequency state of the pole speed regulation.

That is, the same ac motor can only be a constant few synchronous speed; and some process control equipment may need the induction motor in a relatively smooth state of stepless operating speed regulation, which is precisely the excellent characteristics of the variable frequency drive VFD motor.

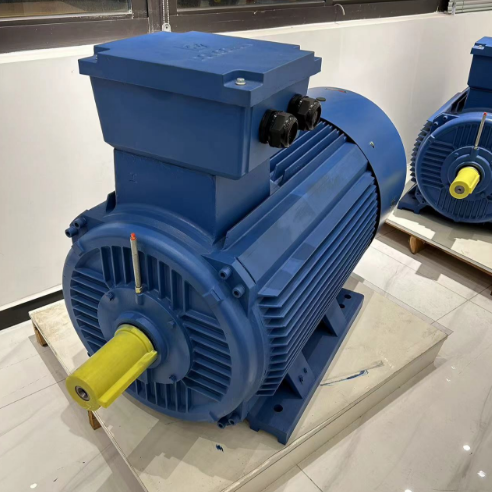

However, in the design and manufacture of the AC induction motors, because of the inverter motor through the inverter rated power supply, as well as the relatively wide range of full speed characteristics, destined to the structure of this type of electric motor is different from the ordinary frequency motor, which can be summarised in the following aspects of process speed control.

Firstly, the specificity of the ventilation structure.

Most low-voltage variable frequency drive VFD motors are self-fan-cooled structures, because the output and desired speed of such AC motor is relatively constant.

As long as there is no obvious overload and the variable voltage and low frequency motor is matched with a reasonable fan, the thermal stability of the normal operation process industrial applications can be met.

However, when the inverter motor is running at low synchronous speed, the structure with its own fan obviously cannot meet its heat dissipation needs, and thus can only be used through a forced ventilation structure, which is the reason why most inverter electric motors have to be fitted with independent fans.

Secondly, the insulation level of the variable frequency drives motor windings is relatively high.

Because of the special nature of the inverter electric motors through the inverter power electronics supply, the input motor power waveform is not a normal sine wave, including the harmonic factors of frequency changes, resulting in the AC electric motors winding to bear more bad impact.

Which requires the induction motors winding insulation level to be higher, general inverter electric motor insulation level can not be lower than F level.

Third, the corona problem control.

Frequency conversion motor winding may have corona problems, thus requiring a special choice of electromagnetic wire, according to different working conditions for output frequency supplied.

Some electric motor manufacturers choose thick varnish electromagnetic wire, the best choice of frequency conversion motor special electromagnetic wire, so that the reliability of the induction motor will be better some.

Fourth, the protection of the bearing system.

Many of the inverter ac motor in the application of bearing system failure, the reason is the variable frequency drives motor shaft current trouble, and therefore in accordance with the size of the ac induction motor specifications and the actual operating characteristics, the bearing system should take the necessary protective measures.

The above 4 tips are for your reference.

Any inquiry for VFD motor , please kindly contact with the professional electric motor manufacturer - Dongchun motor China

Any inquiry, please contact the professional electric motor manufacturer in China as follows:

Dongchun motor has a wide range of electric motors that are used in various industries such as transportation, infrastructure, and construction.

Get a prompt reply.