Efficiency is a very important performance indicator of electric motors, especially under the guidance of energy-saving and emission reduction policies, users of electric motors are particularly concerned about the efficiency index of electric motors.

If the efficiency of the electric motor is to be accurately determined, it is necessary to conduct type tests and through suitable and standardized efficiency test methods.

To determine the efficiency of three-phase asynchronous motor methods, for example, can be broadly divided into three categories.

The first Method is the direct measurement method.

The direct measurement method is intuitive, simple and relatively accurate, but it is not conducive to specific analysis of motor performance and targeted improvement.

The second Method is the indirect determination method,

It was also known as loss analysis method.

Indirect measurement method test items more, time-consuming and laborious, there are more calculations, comprehensive accuracy is not as good as the direct measurement method, but it can show the decision of the motor efficiency of the main components of the specific circumstances, so as to facilitate the motor design, process and manufacturing problems targeted analysis, and through the improvement of motor performance to meet the requirements or further improve; theoretical calculation method is the method used in the test equipment is insufficient, the worst accuracy.

The third Method is the method of using theoretical calculation after a simple test.

It simply called theoretical calculation method.

A method - direct test method of efficiency

The A method, also often called the input-output method, is so named because the two data for obtaining the efficiency, i.e., input power and output power, are obtained directly during the test.

In the test motor plus the specified load, running to temperature stability or after a specified period of time (using the latter method, the temperature reached by the test motor winding and the actual temperature stability of the temperature difference should not exceed 5K), adjust the load in the range of 1.5 to 0.25 times the rated power changes, to measure the load down and up when the two operating characteristics curve.

Each curve should take no less than 6 readings, and each reading includes: three-phase line voltage (should keep the rated value), three-phase line current, input power, speed, output torque, and output power should be recorded when available.

Finally, power off and shutdown, the DC resistance of the stator winding is measured within the specified time, otherwise, the relevant provisions of the thermal resistance should be extrapolated and corrected according to the thermal test.

When available, priority is given to the use of charged measurement (superposition method) or prior to the winding in the buried thermocouple or copper (platinum) RTD and other temperature sensors to obtain the stator winding temperature or resistance at each point of the method.

During the test, the ambient temperature should also be recorded.

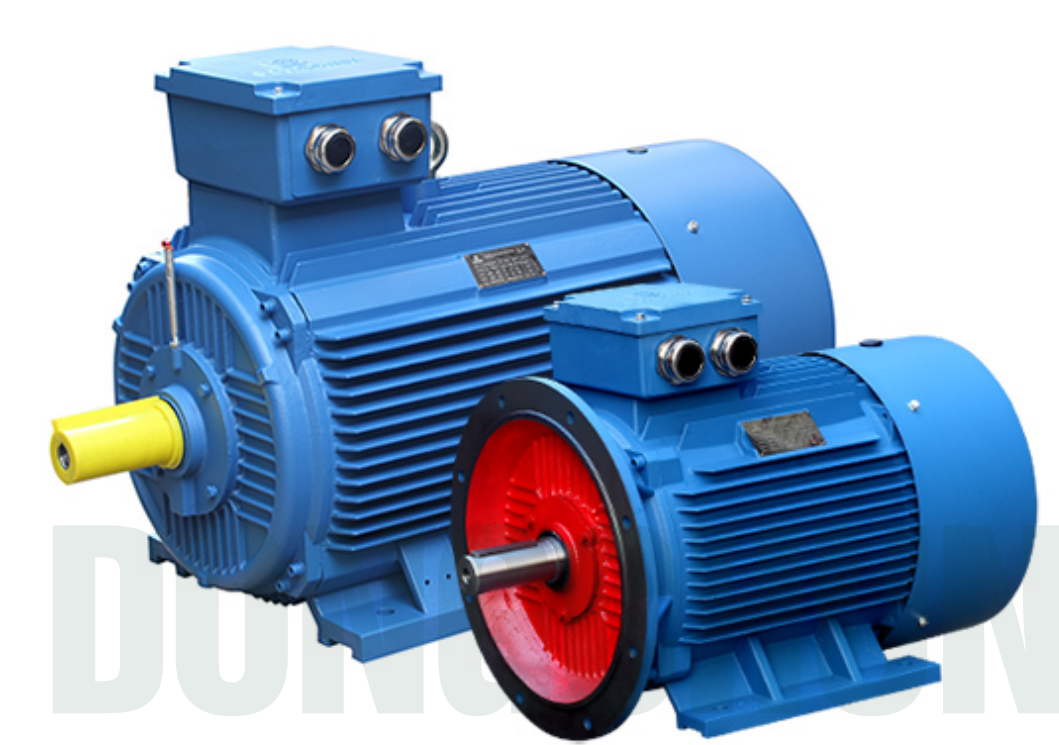

For more information about electric motors, please contact with Dongchun motor China

Dongchun motor is a professional manufacturer of electric motors in China.

Please kindly check the products as follows

single phase motor: YC, YCL with cast iron body and ML , MY motor with Aluminium body

Three phase motor : IE1, IE2, IE3 motor for both cast iron body and Aluminium body

Brake motor: DC brake motor and AC brake motor

VFD motor : frequency variable drive motors.

Get a Free quote from Dongchun motor